Products > Rubber Moulds

Rubber Moulds Manufacturer

JR Rubber Industries is a global leader in manufacturing high-precision rubber moulds for pavers, floor tiles, curbstones, wall tiles, cover blocks, step tiles, manholes, plain slabs, drain slabs, ventilations, boundary walls, and bespoke designs.

We deliver end-to-end paver production solutions.

JR Rubber Moulds

We manufacture a wide range of Rubber Moulds for pavers, Rubber moulds for Floor tiles, Wall tiles moulds, Step Tiles mould, Cover blocks mould, Rubber mould for Drain slabs, Manholes cover mould, KerbStone mould, Rubber mould for Plain slabs, Precast boundary wall mould, Rubber moulds for concrete poles and customized moulds..

Our moulds are recognized for their exceptional durability and backed by service standards that set industry benchmarks. With a footprint covering all states of India and 37 countries worldwide, we have successfully commissioned over 3200 paver units in India and 211 international projects, making us the partner of choice for turnkey paver manufacturing ventures.

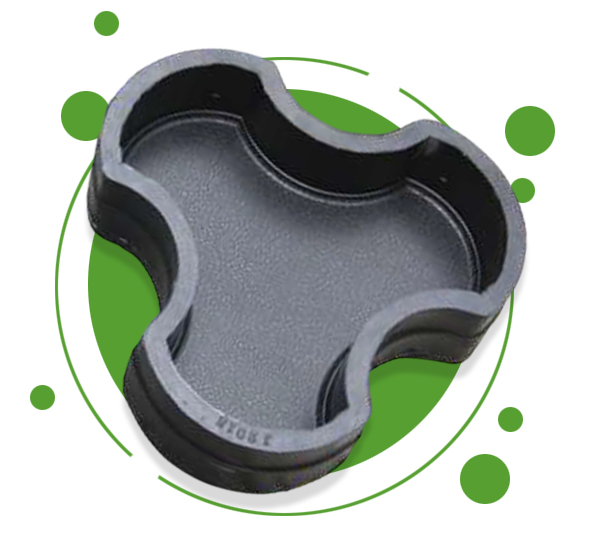

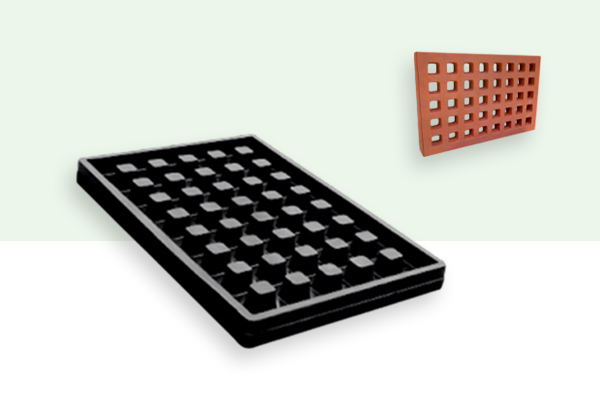

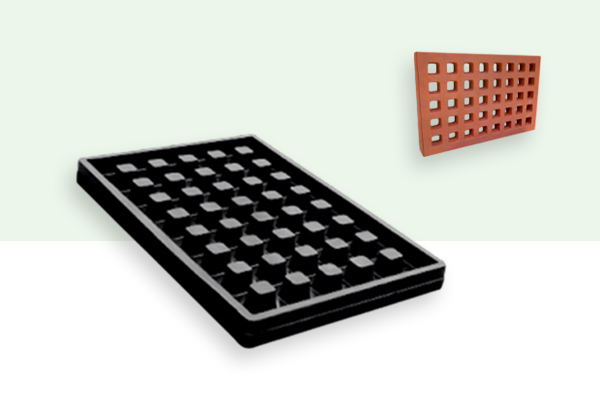

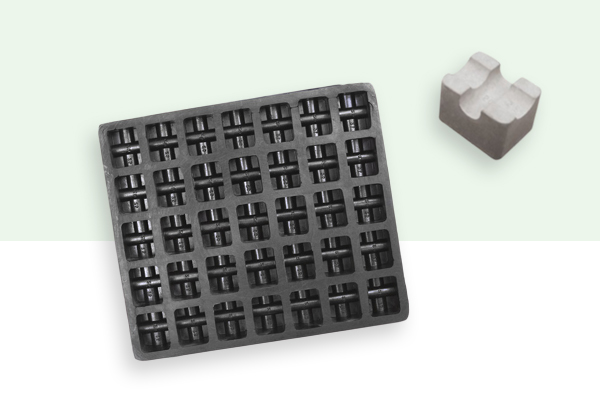

Paver Moulds

Designer Moulds (12)

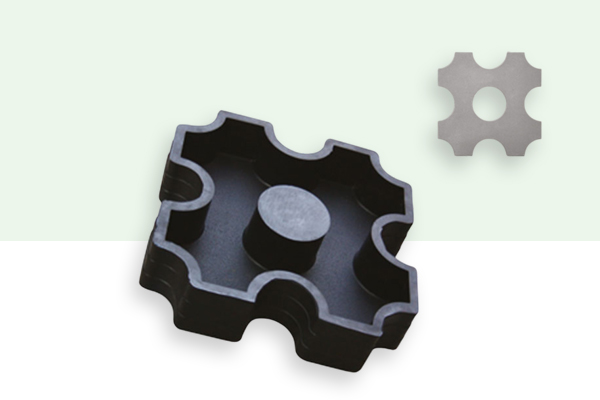

Grass Paver Moulds

Designer Moulds (12)

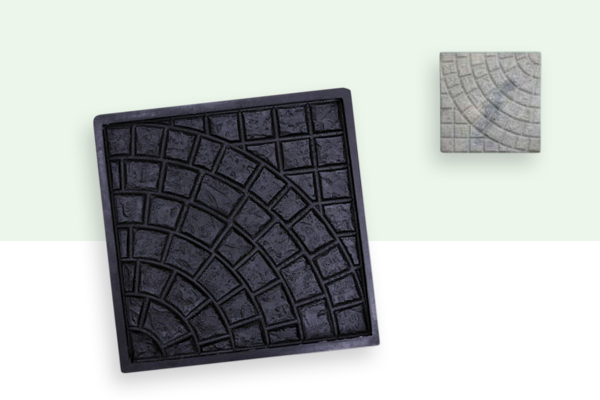

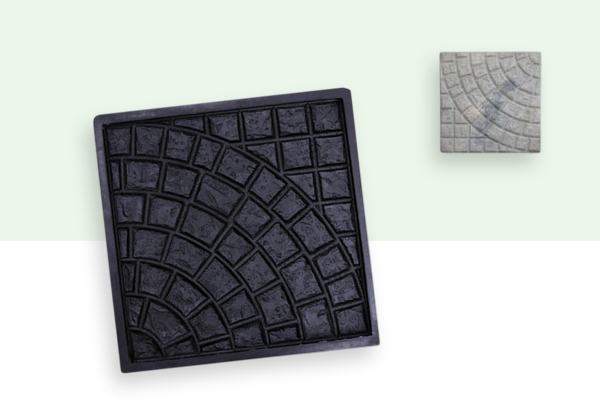

Floor Tiles Moulds

Designer Moulds (12)

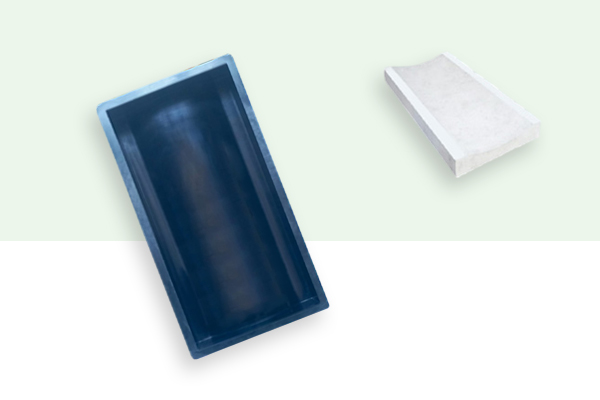

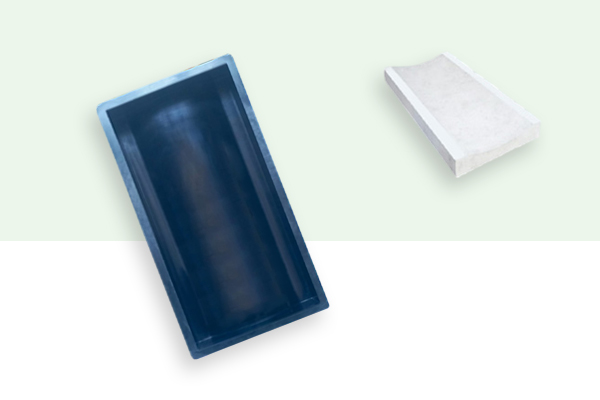

Drain Slab Moulds

Designer Moulds (12)

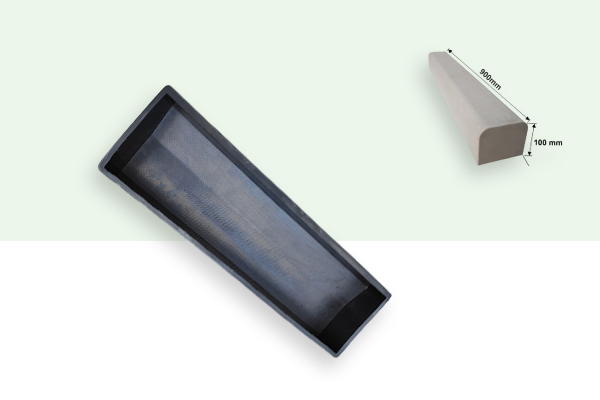

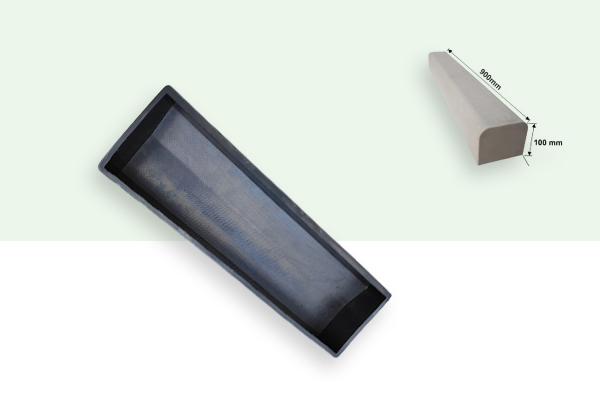

Curb Stone Moulds

Designer Moulds (12)

Vents Moulds

Designer Moulds (12)

Step Tile Moulds

Designer Moulds (12)

Manhole Cover Moulds

Designer Moulds (12)

Cover Block Moulds

Designer Moulds (12)

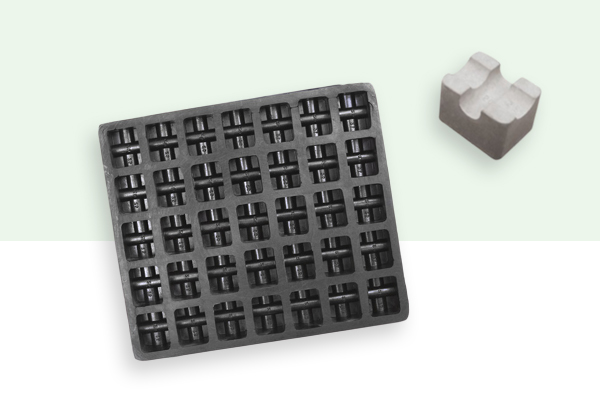

Wall Tile Mould

Designer Moulds (12)

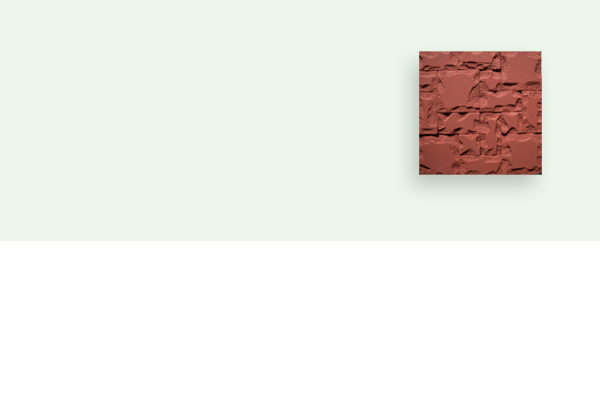

Rubber Moulds Features

- ROur customers when procuring moulds expect for a lifespan of 4-5 years. but across the globe our rubber moulds are used for more than 10 years continuously.

- RVibration of vibrator machine is transferred efficiently to the concrete mix which ensures optimum strength for the paver.

- RLifespan for many years.

- RNo Blackening Or Discoloration.

- RInner layer made of speciality rubber with acid-alkaline resistant, non-stick and anti-static properties.

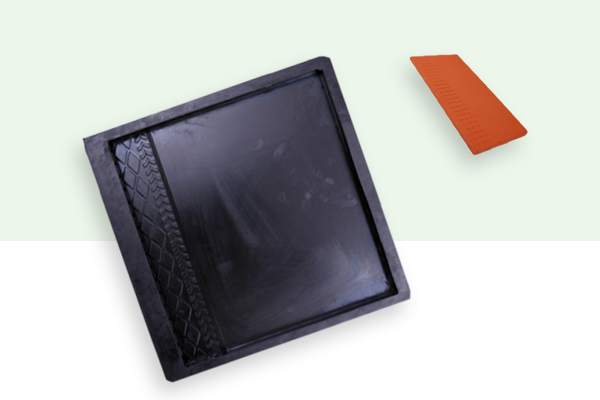

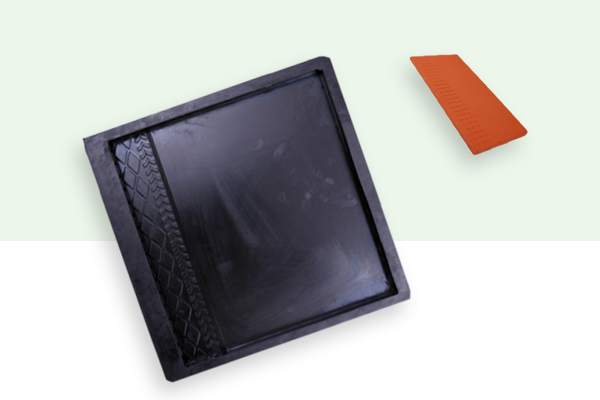

- RStrength and durability similar to automobile tyres

- RAs the paver production does not involve any vigorous application as tyres, the lifespan of moulds is infinite.

Start a Paver Block manufacturing business!

We deliver end-to-end paver production solutions – combining advanced machinery, precision moulds, specialized chemicals, proven technology, and in-plant training. This integrated approach ensures our clients achieve consistent quality, operational efficiency, and long-term success.

Why Choose Jr Rubber Moulds

Established in 1994, JR Rubber Industries brings over two decades of innovation, technical

expertise, and commitment to excellence. Our name stands for premium-grade products and

tailored solutions that evolve with the demands of the global construction market.

Proven Global Experience

With installations in 37+ countries, we understand diverse climates, materials, and production needs. Our solutions are performance-tested across global markets.

Premium Quality Moulds

Our rubber moulds are manufactured with high-grade raw materials to ensure durability, superior finish, and extended mould life cycle.

Turnkey Project Setup

We don’t just sell moulds. We assist in setting up full paver block manufacturing units, from machinery and chemicals to training and production workflow.

Modern Design & Customization

Choose from hundreds of paver designs or request custom mould patterns that match your regional style, brand identity, or project specifications.

On-Site Training & Technical Support

Our expert team provides hands-on training at your facility and ongoing support to ensure efficient production, quality output, and smooth operations.

Long-Term Value & High ROI

Our moulds are built to retain shape, texture, and finish for repeated production cycles, helping you reduce replacement costs and maximize profitability.

Countries - Successful Clients

Established Paver Units Across India

Paver Units Established Across The Globe

Years of Expertice

Best Rubber Mould Paver Block Manufacturers

JR Rubber mould paver block comes in different shapes and designs. We have square paver block design, zig zag paver block design, 3d paver block design, T series, I series, Natural stone designs, Dumbel shapes and many more. You name it! We can also design and develop customized moulds and also interlock moulds as per your requirement.

We manufacture Rubber moulds intended for long service life. Rubber moulds are strong, flexible which makes demoulding easy. Rubber moulds have high inner finishing, even the fine textures on moulds are effectively transferred to pavers. Paver manufactured in rubber moulds with vibro forming technology have high compression strength. Any textures are possible to make in Rubber moulds. Natural stone pavers can be cast with perfection with JR Rubber moulds. Plain slabs with mirror-like finished surfaces can be cast due to the high glossy inner finish of Rubber moulds. A wide combination of textures and impressions is possible to be cast in Rubber moulds.

We manufacture large-sized moulds for precast boundary walls, poles, manholes, curb stones, drain slabs and moulds for other special concrete products. Rubber moulds give zero production damages since demoulding and handling of moulds are comfortable with rubber moulds.

We have a client base in India and 34 countries around the world. We have experience in establishing over 1600 paver units in India and 72 units across the globe. We provide end-to-end solutions for businesses and entrepreneurs to establish successful paver factories. The company was established in 1993 and over the past 29 years, we have become the pioneers in manufacturing the finest quality rubber products for over two decades. Customers trust us for our premium products and personalized solutions. Our rubber moulds are widely used in countries like Kenya, Tanzania, Somalia, Rwanda, Malawi, Zambia, Malawi, Niger, Zimbabwe, Uganda, Sri lanka, UAE, Oman, Vietnam, Malaysia, Qatar, Saudi arabia, etc. Our rubber moulds give maximum finish to the tiles and paver blocks due to the mirror finish inside the moulds.

The elasticity and resilience of our rubber moulds transfers the vibration of the vibrating table efficiently to the compound. The rubber moulds give maximum strength and density to the paver blocks. The non-sticky inner layer guarantees easy demoulding of tiles and paver blocks and avoid constant cleaning of moulds. The chemical resistant inner layer is the unique feature of our rubber moulds that makes them incomparable with our competitors.

End-to-End Paver Manufacturing Solutions

JR Rubber Industries delivers complete solutions for paver block manufacturing, from moulds and machinery to turnkey plant setup and operational support. We ensure seamless production, consistent quality, and long-term value for entrepreneurs, contractors, and large-scale industries across the world.

Design and develop customized moulds.

In-Plant Training for Client Personnel Support

Design, engineering, supply & installation of machineries

Supply of chemicals & color oxides

Paver production assistance anywhere in the world.

Onsite machinery fabrication and installation anywhere in East-Africa.

Start Your Paver Manufacturing Journey With JR Rubber Industries

From nationwide installations to worldwide project deployments, our expertise spans continents. We continue to expand our service footprint, ensuring reliable supply, training, and technical support wherever our clients operate.