Vibrating Table For Cabro Making In Kenya

The demand for high-quality cabro materials is pivotal in Kenya’s dynamic construction industry. At JR Rubber Industries, we understand the critical role played by Cabro in Kenya’s construction projects. Our specialised vibrating table for cabro making in Kenya is meticulously engineered to enhance the production process, ensuring durability and top-notch quality across diverse construction endeavours in the region.

Kenya’s construction landscape relies on durable and reliable cabro materials. At JR Rubber Industries, we recognize the significance of this material in Kenya’s projects. Our vibrating table for cabro making in Kenya is designed to elevate the production process, ensuring longevity and superior quality in every construction endeavour across Kenya’s diverse terrain.

At JR Rubber Industries, our mission is to redefine the standards of quality and durability in construction materials. We strive to provide cutting-edge solutions that not only meet but exceed the expectations of our customers in Kenya’s dynamic construction sector.

Product Overview

JR Rubber Industries presents a state-of-the-art vibrating table designed meticulously for the specific needs of cabro production in Kenya’s construction industry. This specialized equipment stands as a cornerstone for superior cabro quality, durability, and seamless production processes across varied terrains and conditions in Kenya.

Key Features

Precision Engineering

Our vibrating table is crafted with precision engineering, ensuring optimal performance and reliability, meeting the demanding standards of Kenya’s construction industry.

Durable Construction

Explicitly engineered for cabro making, the table enhances the quality and resilience of cabro materials, ensuring durability in Kenya’s diverse construction projects.

Easy To Operate

User-friendly controls make operation hassle-free.

Enhanced Productivity

Accelerate your production process, delivering pavers faster.

Vibration Frequency

Ensures thorough compaction and minimizes air bubbles.

Table Size

[Machine dimensions: 10 Ft length * 2.75 Ft width *2.96 Ft height]

Compliant with Standards

Meets industry standards for quality and performance.

Customizable Settings:

Adjust vibration intensity to match your specific requirements.

Paving The Way To Excellence.Our Happy Clients Across Kenya

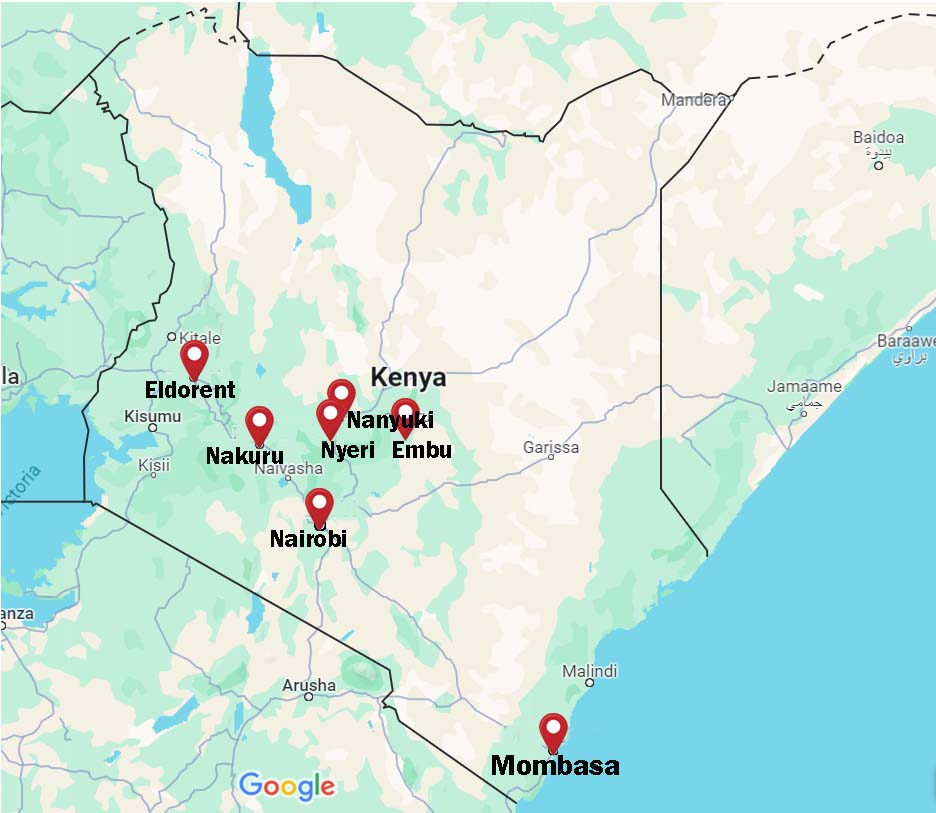

Nairobi, Embu, Nyeri, Nanyuki, Nakuru, Mombasa and Eldoret have embraced our premium paver moulds with open arms! At the heart of Kenya’s urban hubs and scenic regions alike, our moulds have become cornerstones of transformative projects, seamlessly merging functionality and aesthetic elegance into transformative projects that bring life-transforming projects to fruition.

Specifications

- Dimensions: 10 Ft length * 2.75 Ft width *2.96 Ft height

- Maximum size of tile: 2 Ft x 2 Ft (Recommended)

- Maximum Height of tile: 100mm (Recommended)

- Movement of Rubber Mould : Automatic

- Production Capacity:

- Tiles: 3000 Sq. Ft/ 8 Hour Shift

- Interlock Paving Block (60mm): 2000 Sq. Ft / 8 Hour Shift

Our Services

Why Choose JR Rubber Industries ?

If you’re working in the field of paving, then you’re aware that efficiency and maintaining quality standards are essential. At JR Rubber Industries, we know your needs and proudly unveiled our revolutionary Vibrating Table to Paver, Plastic Paver Moulds, and Rubber Mould Paver making.

Our cutting-edge products are designed to revolutionize the production process. If you’re in search of accuracy with rubber mould paver making or the flexibility of moulds for pavers made of plastic, We’ve got it covered.

Contact us today to learn more about the many possibilities of creating the most impressive production set-up in the business. Efficiency and quality are our primary goals, so we’re ready to assist you in getting the most effective outcomes from your paver projects.

If you select one of our concrete Vibrating Table to use for Paver Making, you benefit from

Related Videos

How To Order

To order our vibrating table for cabro making in Kenya, you may visit our website, WhatsApp for a quick reply or click the Contact Us button below.

Frequently Asked Questions (FAQs)

1. How is JR Rubber Industries adapting its vibrating table for Kenya's cabro production?

At JR Rubber Industries, our vibrating table is specifically engineered and designed to meet the unique requirements of cabro production in Kenya. We incorporate precision engineering and robust features tailored to address the specific needs of Kenya’s construction industry, ensuring seamless and superior performance in cabro making processes across varied terrains and conditions in the region.

2. Can I receive a demonstration of the table's functionality specific to Kenya's conditions?

Absolutely! We understand the importance of witnessing the table’s performance within the context of Kenya’s construction conditions. Our team provides comprehensive demonstrations tailored to Kenya’s environment. This demonstration ensures that you experience firsthand how our vibrating table optimizes cabro making in Kenya’s diverse construction projects.

3. Are there any special considerations for maintenance within Kenya's climate?

Yes, our maintenance packages are specifically designed to address Kenya’s climate and terrain. We factor in the unique environmental conditions to ensure longevity vibrating table peak performance within Kenya’s diverse climate. Our maintenance services are tailored to withstand the challenges posed by Kenya’s environment, ensuring your table operates at its best.

Get In Touch

Contact

JR RUBBER INDUSTRIES

+91 85 899 55 445

mail@jrrubbermoulds.com