Rubber Moulds for Precast Compound Walls

We introduce our high-performance Rubber Moulds, engineered for compound walls, fences, and panel casting.

Designed for vibroforming technology, these moulds ensure superior surface quality, dimensional accuracy, and structural strength in every panel.

Engineered Rubber Mould Solutions for High-Precision Precast Concrete Products

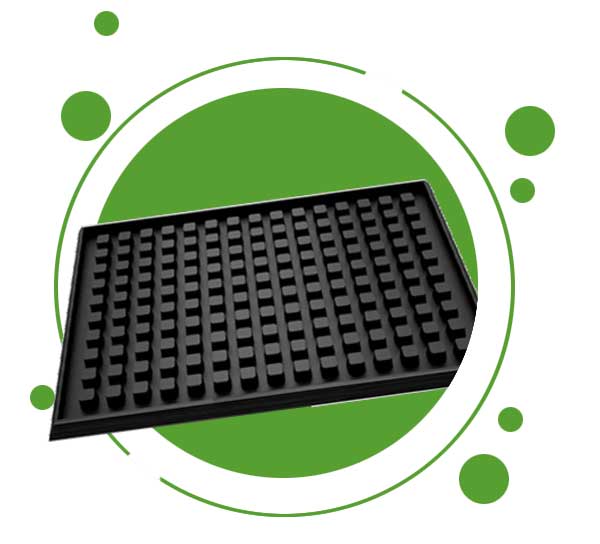

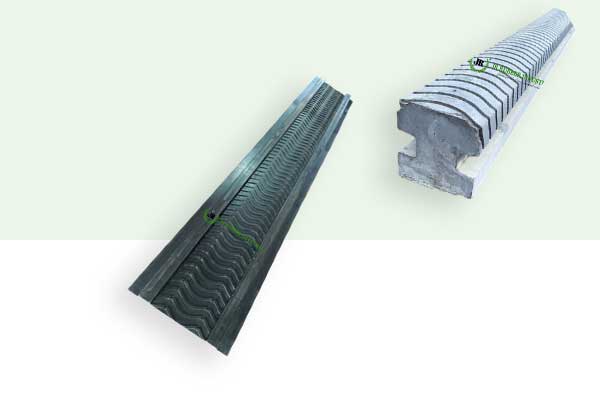

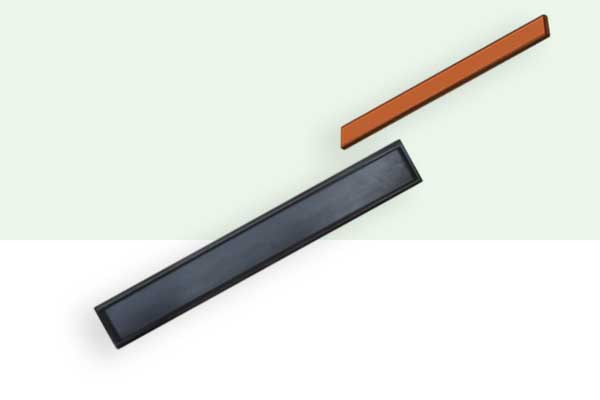

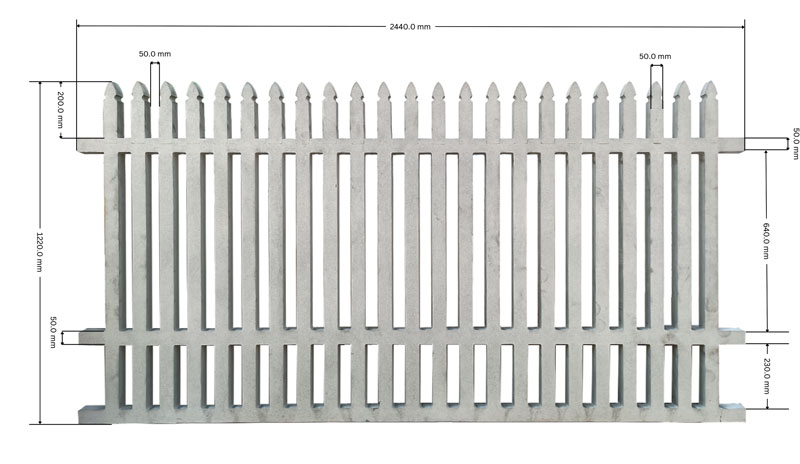

Precast Boundary Wall Rubber Moulds

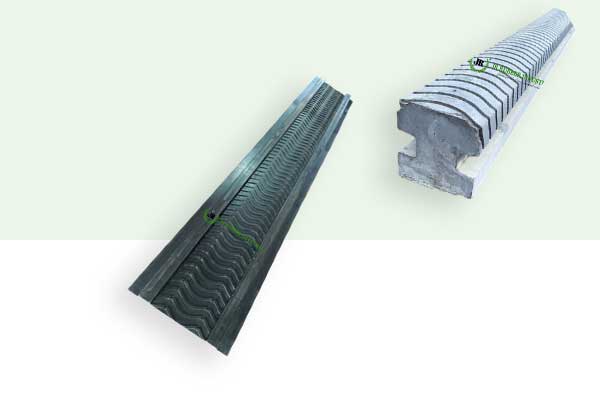

Precast boundary walls casted in Rubber moulds have unmatched finishing,glossy finish. The moulds with concrete mix are Vibro formed which gives the concrete products high strength. Reinforcements and Glass fiber can be included in admixture to improve strength of panels.

All elements of compound walls are precast in factory and are installed at site. Colours and design is inbuilt. Rubber moulds are flexible and easy to demould. This also ensures zero damage production. The production can be done even in a small factory setup and scale upto large production plants for mass production. We have moulds with various designs and textures,mould designs with perforation which are only possible to be casted in Rubber moulds.

Wall Panels

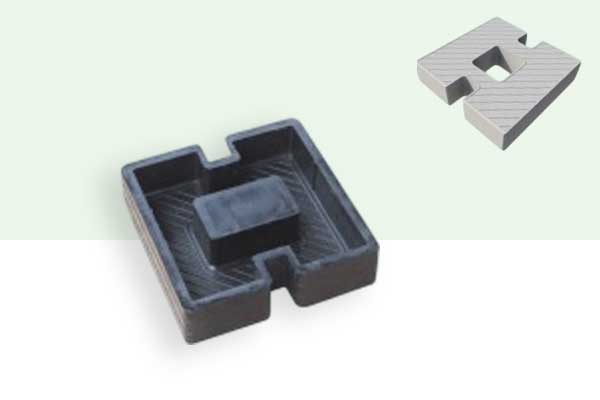

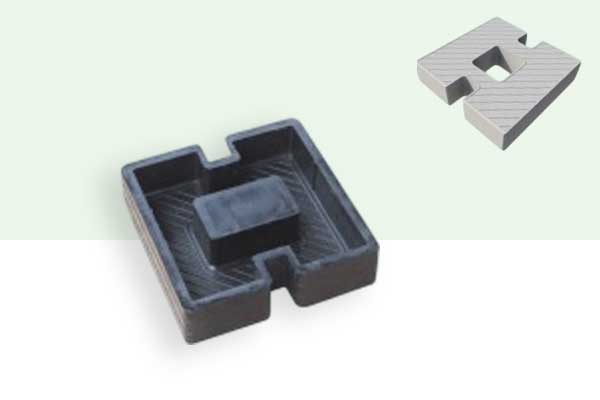

Pillars

Single Pole

Copings

Features of Precast Compound Walls Mould

- RHigh Density Concrete – Vibration compacts the mix uniformly, reducing voids and porosity.

- RSuperior Surface Finish – Rubber mould flexibility ensures flawless texture replication with natural glaze.

- REnhanced Durability – Dense compaction increases resistance to weathering, moisture ingress, and cracking.

- RDimensional Accuracy – Consistent panel thickness and sharp edges for easy installation and alignment.

- RSuperior Bonding – Vibro-compacted surfaces offer better adhesion for finishes and coatings (if required).

- RLoad Bearing Capacity – High compressive strength panels ideal for compound and boundary wall applications.

- RAesthetic Excellence – Integrated colors and intricate designs directly embedded during casting.

- RReduced Maintenance – Glazed, compact panels resist dust accumulation and surface erosion.

- RFast Turnaround – Easy de-moulding and quick curing cycles accelerate project timelines.

- RScalable Production – Suitable for both small-scale and industrial precast units.

Start a Precast Wall Manufacturing Business!

We deliver end-to-end precast wall production solutions, combining high-precision wall moulds, advanced machinery, specialized admixtures, proven curing techniques, and on-site training. This integrated approach ensures consistent wall quality, faster installation cycles, reduced manpower dependency, and long-term manufacturing efficiency for your business.

Why Choose Jr Rubber Moulds

Established in 1994, JR Rubber Industries brings over two decades of innovation, technical

expertise, and commitment to excellence. Our name stands for premium-grade products and

tailored solutions that evolve with the demands of the global construction market.

Proven Global Expertise

With installations in 37+ countries, we understand diverse climates, materials, and production needs. Our solutions are performance-tested across global markets.

Superior Surface Finish

Our rubber moulds deliver smooth, uniform panel surfaces with refined textures and natural glaze, enhancing the final aesthetic without extra finishing work.

High Dimensional Accuracy

Precision mould engineering ensures consistent thickness, sharp edges, and perfect alignment, making installation faster and hassle-free on site.

Faster Production Cycles

Easy demoulding and quick curing support higher output with fewer labor requirements, enabling efficient scale-up of manufacturing operations.

Versatile Design Options

From plain to decorative patterns, panels can be customized to match architectural themes, creating premium visual appeal in boundary and compound walls.

High-Density, Durable Panels

Vibroforming technology compacts concrete evenly, resulting in stronger, weather-resistant panels that last longer with minimal maintenance.

Countries - Successful Clients

Established Paver Units Across India

Paver Units Established Across The Globe

Years of Expertice

End-to-End Paver Manufacturing Solutions

JR Rubber Industries delivers complete solutions for precast wall production, offering high-precision rubber moulds, production systems, and end-to-end setup assistance. Our moulds ensure accurate dimensions, smooth finishes, and strong structural performance suitable for residential, commercial, and infrastructure applications. We support contractors, architects, builders, and precast manufacturers worldwide with reliable quality, seamless installation, and long-term durability in every project.

Design and develop customized moulds.

In-Plant Training for Client Personnel Support

Design, engineering, supply & installation of machineries

Supply of chemicals & color oxides

Paver production assistance anywhere in the world.

Onsite machinery fabrication and installation anywhere in East-Africa.

Start Your Precast Wall Manufacturing Journey With JR Rubber Industries

Precast compound walls are a time saver as the installation time is very less. Also, with precast compound walls, you can save the labour cost as we will do the installation for you. Our compound walls are also very strong. We export our moulds across the world to countries like Uganda, Kenya, Somalia, Tanzania, Kenya, UAE, Sudan, Zambia, Qatar, Oman, Saudi Arabia, Vietnam, Ethiopia, USA, Cameroon, Bangladesh, Mauritius, Malaysia, Mali, Nepal, etc.