7 Reason To Choose The Precast Compound Wall

A precast compound wall is a type of boundary wall that is pre-manufactured in standardized sections off-site and then transported to the construction site for installation. These walls are made using precast concrete or other materials. The process involves casting the concrete in moulds allowing it to harden before being transported to the location where it will be installed.

JR Rubber Industries specializes in manufacturing a wide range of Rubber moulds for precast walls in various designs and sizes. Our product range includes Rubber moulds for precast boundary wall panels, poles, coping, boundary wall base and all other elements required for the compound wall. All the elements of the wall are precast in our factory and installed on-site. Our Rubber moulds are flexible and easy to demould, ensuring zero damage production. With inbuilt colors and designs, we guarantee a flawless finish for your compound wall.

Types Of Compound Walls

Our products include:

- Precast compound wall moulds.

- RCC boundary walls.

- Compound wall moulds.

- Ready-made compound walls.

In comparison to stone walls and brick walls, precast compound walls are economical. Gorgeous designs can be created using precasting, which is not possible by masonry.

Precast compound walls can be time-saving as the time for installation is significantly smaller. Additionally, with the precast wall and structures can be automated quickly.

Difference Between Traditional Wall And Precast Compound Wall

Traditional Wall

- Traditional construction typically involves on-site assembly of building components. Raw materials such as bricks, blocks and mortar are applied and formed directly at the construction site.

- Traditional construction methods often require extended time frames due to on-site fabrication and curing processes. Weather conditions can impact construction schedules, leading to delays

- Involves a higher demand for on-site labor for tasks. Labour costs can be a major portion of the overall project expenses.

- Customization of designs can be limited, especially for complex architectural elements. Achieving uniformity in designs may be challenging.

- Quality control is more challenging when it comes to on-site construction, and variations in construction quality may occur. It also depends on the skill level of on-site workers.

Precast Compound Wall

- Precast walls involve the manufacturing of individual panels off-site. These pre-made panels are transported to the construction site for assembly.

- Installation is faster due to the pre-constructed components. The time required to complete the project is minimal.

- The labor tasks are moved off-site reducing the need for extensive on-site labor. Assembling precast panels requires fewer workers and can be more automated.

- Precast walls offer high design flexibility with a range of textures, patterns and finishes. Designs can be achieved through precision moulding techniques

- Quality control is enhanced in the controlled factory environment, ensuring consistent panel quality. Panels are produced to precise specifications reducing variations in the final product.

MouldsFor Precast compound Walls

Precast compound walls moulds including coping mould, domes, wall panels and pillars, play a crucial role in the manufacturing process .

COPING MOULD

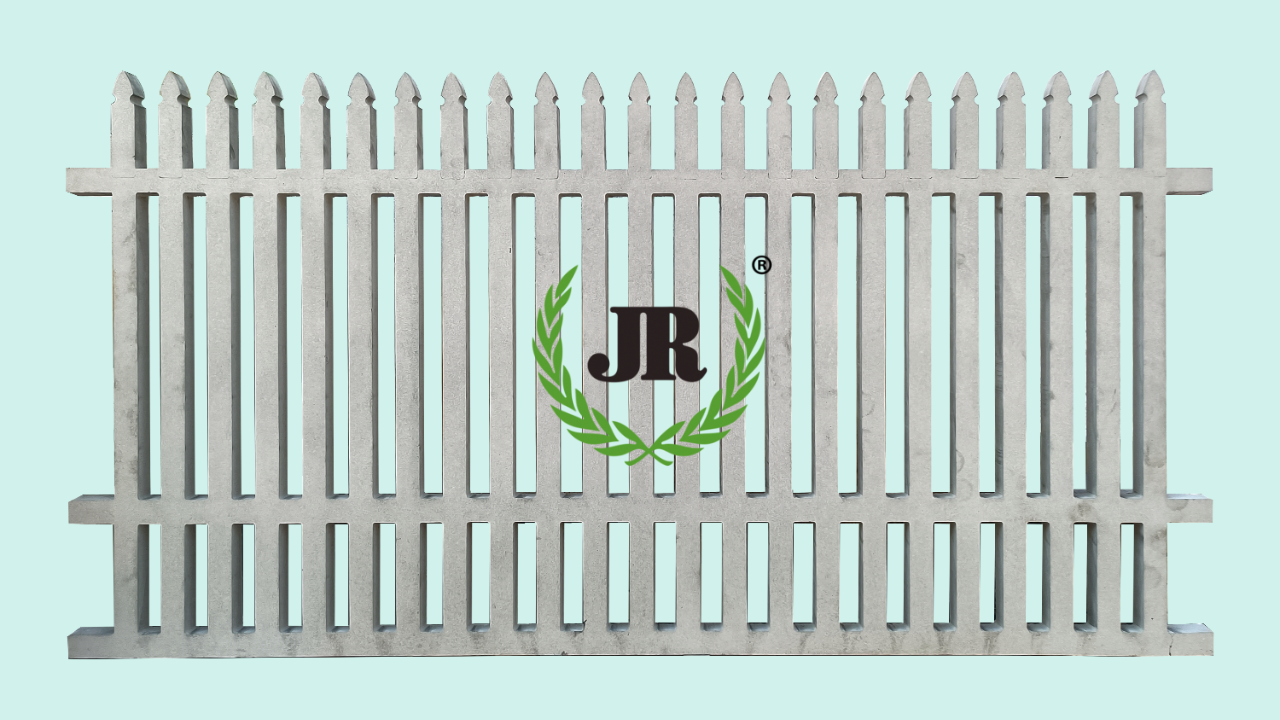

WALL PANEL

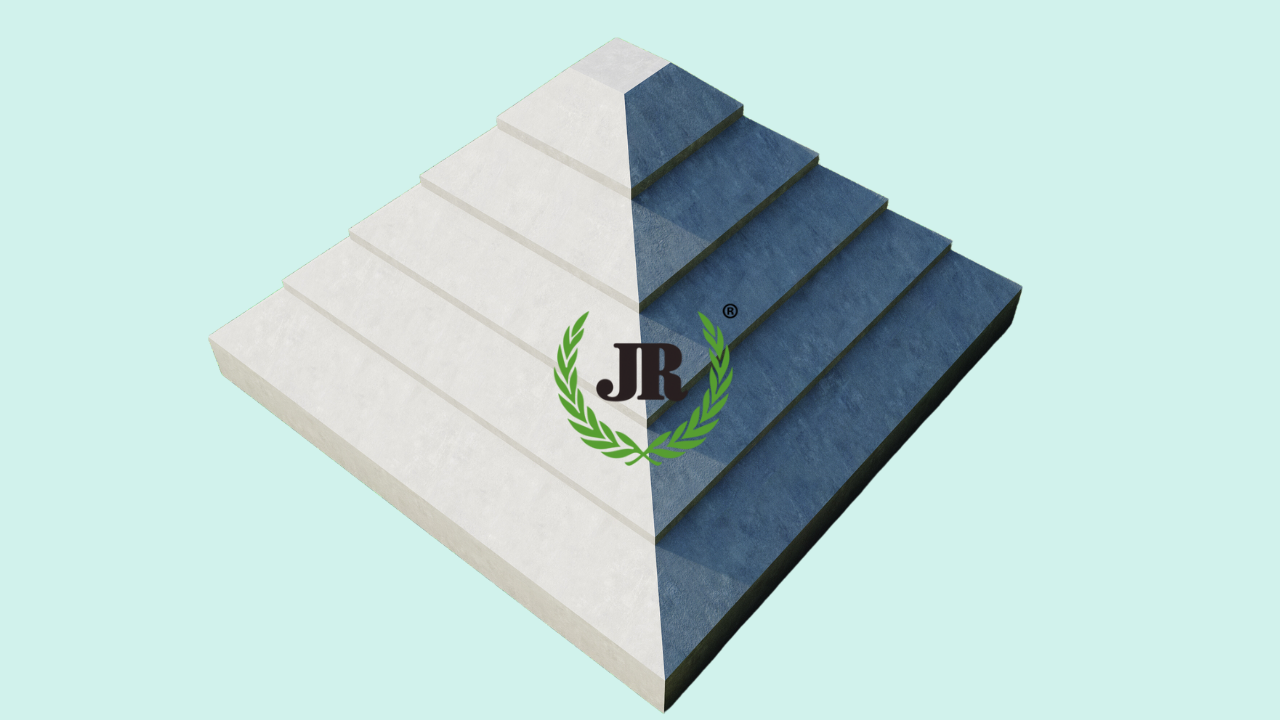

DOME

PILLAR

Reasons To Choose Precast Walls

Precast walls are gaining popularity due to their numerous advantages. Precast is becoming more popular due to benefits such as speedy installation and fire resistance. It is a tested and proven theory that has been employed in various industries, infrastructure, public buildings, commercial projects and small residential structures.

Some of the advantages of using precast compound walls over traditional methods of building are listed below:

1. Save Time

This is the primary reason why precast blocks are gaining popularity. If you are working on a large project, speed is critical. Precast panels save time since when they arrive at a construction site, the pieces are ready to install, all that is required is correct assembly. Installation of precast concrete panels is often quicker and more straightforward than traditional construction methods.

JR Rubber Industries manufactures compound wall rubber moulds for all the parts on-site and then transfers them to the construction site for further installation.

2. High Strength

The consistency in the quality of raw materials used and the quality of concrete gives a perfect and precise precast wall stronger than normal walls.

The moulds of JR Rubber Industries play a crucial role in building stronger precast walls. Our moulds are adapted to accommodating diverse raw materials and shaping them into perfect designs to meet regulatory requirements.

3. Quality

A Precast wall is manufactured under strictly regulated conditions and to precise specifications ensuring consistent quality. The precision and predictability of a concrete wall are addressed. This reduces the chances of any variations or defects compared to on-site construction where factors like weather .

4. Versatility in Height and Length

Precast walls can be manufactured in varying heights and lengths, catering to different property requirements. This versatility makes them suitable for various applications, from residential properties to commercial developments.

We use rubber as the raw material which involves effortless moulding and demoulding processes, facilitating the construction of walls to align effortlessly with any specified requirements.

5. Low maintenance

Precast compound walls typically require minimal maintenance. The materials used are resistant to weathering, and the smooth surfaces make them easy to clean. An existing precast construction can be easily modified, enlarged, or removed. The panels are made strong, so they stay for a long time without any problems.

Our moulds have been effectively preserved ensuring a long lifespan and extended durability.

6. Predictable Project Schedule

Precast construction allows for better project scheduling and predictability of the completion date. Delays due to weather conditions are minimized since the manufacturing process occurs in a controlled environment.

Our site is well-equipped with all the necessary facilities to perform procedures without being affected by weather conditions and maintaining efficiency.

7. Aesthetic Appeal

The Precast wall’s aesthetic potential has increased its popularity. These frameworks can include a wide range of shapes and finishes, from fine-grained to rough, as well as any patterned textures you desire.

The precast wall comes with a textured finish on both sides of the wall. This gives a modern boundary wall design around your home. Precast wall design is extremely well built and lasts longer than stone boundary wall designs.

Quickly browse the range of designs we have uploaded on our website for your reference. We offerings unparalleled wall moulding designs and quality. The readymade compound wall price may fluctuate based on the chosen design.

Images Of Our Precast Boundary Walls

Welcome to a visual exploration of the world of precast boundary walls! In this collection of images, we invite you to discover the craftsmanship and aesthetic appeal precast boundary walls can offer. Recognize the potential for design aspirations and construction practicality. Allow these images to serve as your gateway to a world of designs that help you determine the service that aligns with your needs.

Conclusion

In conclusion, precast walls have become a modern and efficient solution for construction projects. Their speed of installation, design flexibility, durability characteristics make them a preferred choice for developers looking to streamline the construction process while adhering to high-quality standards and environmental considerations.

Prefabricated compound walls stand out as a time-efficient solution requiring minimal installation time. Our compound walls efficient in time effective , but they also have exceptional strength. We extend our service areas globally, exporting our moulds to numerous countries such as Uganda, Kenya, Somalia, Tanzania, UAE, Sudan, Zambia, Qatar, Oman, Saudi Arabia, Vietnam, Ethiopia, USA, Cameroon, Bangladesh, Mauritius, Malaysia, Mali, Nepal, and more. JR Rubber Industries is proud to deliver quality and innovation.