Paver block mould play an essential role in shaping the construction industry by enabling the production of long-lasting, visually appealing, and hardscaping elements. Their adaptability and versatility make them an important asset in both manufacturing facilities and construction sites, where they play an essential role in molding landscapes and outdoor spaces.

JR Rubber Industries manufactures the best-quality paver block molds. With our extensive experience and expertise, we strive to continuously innovate and improve our products to meet the evolving needs of our customers. Our molds are made from durable materials that can withstand heavy usage and extreme weather conditions. Additionally, we offer a wide range of designs and sizes to cater to the diverse needs of our customers.

1. Key Features of Paver Block Moulds

Paver block moulds are essential for shaping and creating a variety of interlocking concrete or cement pavers. These features are instrumental in the production process and the versatility of paver designs. Here are the key features of paver block molds:

- Material Composition: It’s important to select the material composition of the paver block molds based on the project’s requirements & durability. We have rubber, plastic and PVC paver molds.

- Design and Shape: The selection of a specific design and shape for paver block molds is a creative process that depends on the desired aesthetic, the project’s theme, and the landscaping goals. We have a wide range of paver block designs to achieve the desired look and functionality for outdoor spaces.

- Size and Dimensions: Paver block moulds are designed with specific dimensions, and these moulds are available in a variety of designs . JR Industries also provides customized designs. The selection of size and dimensions depends on the project’s design, aesthetic goals, and functional requirements.

- Durability: The durability of paver block molds is a crucial factor in ensuring the longevity and quality of the interlocking concrete or cement pavers they produce. The durability of these molds is essential to maintain precise dimensions, produce consistent pavers, and withstand the demands of the manufacturing process.

2. Types Of Paver Block Moulds

1. Rubber Paver Mould

Rubber paver mould is the type of mold used in the production of interlocking concrete or cement pavers. These molds are made from rubber materials and are designed to create various paver designs with intricate textures and patterns. And also we provide combination moulds. Some key features of rubber molds are:

- Flexibility

- Texture Replication

- Custom design

- Ease of demolding

- Consistency

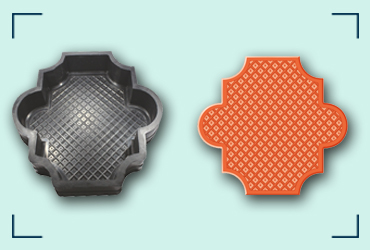

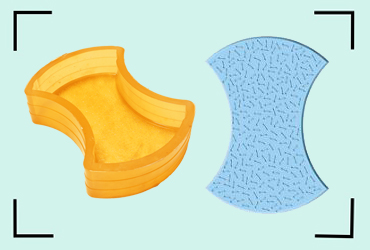

Rubber Paver Block Mould Designs

2. Plastic Paver Moulds

Plastic paver moulds are made of plastic used to make concrete, or other similar substances to make pavers. The molds are available in different sizes and shapes, which allows for the creation of various kinds of pavers that have unique designs.. There are some features are:

- Durability

- Ease of Use

- Affordability

- Lightweight

- Weather Resistance

Plastic Paver Moulds Designs

3. PVC Paver Moulds

PVC paver moulds are specialized molds used in the production of interlocking concrete or cement pavers. These molds are made from PVC (Polyvinyl Chloride) material and offer various advantages for creating pavers with different designs and patterns. Key features are:

- Easy of demolding

- High finished pavers

- First-quality molds with long lifespans.

- Fine and smooth finished pavers.

PVC Paver Moulds Designs

3. Benefits of Paver Block Moulds

Paver block moulds are versatile tools that enable efficient and customized paving solutions, making them popular in landscaping, construction, and home improvement projects.

- Design Flexibility: Paver block moulds come in various shapes and patterns, allowing for creativity and customization in design, which can enhance the visual appeal of driveways, walkways, patios, and other paved areas.

- Ease of Installation: Pavers created with molds are relatively easy to install and replace if needed.

- Interlocking Capabilities: Many paver block moulds are designed to interlock, creating stable and uniform surfaces that are less prone to shifting.

- Customization: Molds can be used to produce pavers in specific colors and textures to match the project’s aesthetic requirements.

- Replicability: Molds ensure consistent and uniform paver production, which is essential for larger projects with numerous pavers.

4. Maintenance & Storage

Maintenance

- Regular Cleaning: Establishing a regular cleaning schedule is to prevent the accumulation of concrete residue and to maintain the mold in prime condition for future use.

- Avoid Using Harsh Chemicals: Harsh chemicals cause surface damage to paver block moulds. Use mild chemicals for their durability.

- Inspect for Damage: Regular inspection of the molds for any signs of cracks, or damage. Address any issues promptly to prevent further damage.

- Release Agents: If necessary, use a release agent like oil or silicone spray to prevent concrete from sticking to the mold. Follow the manufacturer’s recommendations for the type of release agent to use.

- Proper Handling: When moving or transporting molds, do so carefully to avoid dropping or banging them, which can lead to damage.

Storage

- Clean and Dry: It is essential to ensure the molds are cleaned well and fully dried before storing them. Otherwise, moisture causes mold growth and deterioration of the molds.

- Stacking: If molds are stackable, stack them neatly to save space. Place a protective layer, such as cardboard or foam, between molds to prevent scratching or sticking together.

- Cover or Enclose: If possible, cover the molds with a cloth or plastic sheet to protect them from dust and dirt. Some molds may come with storage bags or cases for this purpose.

- Temperature Control: Store molds in a dry and temperature-controlled environment. Temperature variations can affect the durability of the molds.

- Organize and Label: If you have multiple molds, organize and label them so that you can easily find the specific mold you need for future projects.

- Keep Them Level: Store molds on a level surface to prevent warping or distortion over time.

- Avoid Overloading: Do not place heavy objects on top of the molds, as this can deform or damage them.

5. Innovations & Technological Advancements

Innovations in the technological advancement of paver block moulds have contributed to improved efficiency, sustainability, and design possibilities in the construction and landscaping industries. Here are some notable innovations:

- 3D Printing: Utilizing 3D printing technology to create paver block moulds offers the flexibility to produce intricate and customized designs with precision. This allows for unique and complex patterns that were difficult to achieve with traditional molds.

- Smart Molding Machines: Advanced paver block machine equipped with sensors and automation features can optimize the concrete pouring process, reducing waste and ensuring consistent quality. These machines can also adjust to different mold designs quickly.

- Modular Molds: Modular molds that can be assembled in various configurations enable the creation of diverse patterns and designs, making it easier to achieve complex hardscaping layouts.

- Digital Design Tools: Software and digital tools are available to assist in designing custom paver block molds with precision and efficiency, reducing the associated with mold design.

- Interlocking and Permeable Features: Molds with improved interlocking and permeable designs are now available, facilitating the creation of stable paved surfaces.

- Customizable Textures: Innovations in mold surface textures allow for the production of pavers with different finishes, such as natural stone or wood textures.

Conclusion

In conclusion, paver block moulds play an important role in the construction and landscaping industries, offering a wide spectrum of benefits. They provide design flexibility, and durability in creating custom-designed paved surfaces. Maintenance and proper storage are essential for ensuring the longevity of these molds.

Our experience in our industry, we have established a strong reputation for delivering reliable and efficient solutions. Our team of skilled professionals ensures that each mould is crafted with precision and attention to detail. Whether you need moulds for paving, wall cladding, or any other application, we have the perfect solution to meet your requirements. JR Rubber Industries give best quality and customer satisfaction.