New Model Interlock Designs 2026 | Rubber Mould Pavers

The paving industry is rapidly evolving, and 2026 brings a fresh wave of innovation in interlock paver designs. With growing demand for durability, aesthetics, and faster production, rubber mould interlock designs are becoming the preferred choice for manufacturers and contractors worldwide.

In this blog, we explore the latest new model interlock designs for 2026, trending patterns, size standards, and why rubber moulds are dominating the global paving market.

Why Interlock Paver Designs Matter in 2026

Modern infrastructure and landscaping projects demand more than basic paving. Interlock designs now focus on:

Enhanced load-bearing strength

Premium stone and texture finishes

Faster demoulding and longer mould life

Visual appeal for residential & commercial spaces

Rubber mould technology enables precise detailing and consistent output, making it ideal for next-gen interlock designs.

New Model Interlock Designs 2026 – Key Trends

🔷 1. Geometric & Modular Patterns

Clean lines, angular layouts, and modular interlocks are dominating 2026 designs. These patterns offer:

Seamless alignment

High strength interlocking

Premium modern appearance

Popular in urban walkways, driveways, and public spaces.

🔷 2. Stone Texture & Natural Finish Designs

Stone-finish interlock designs continue to trend due to their:

Natural granite / slate appearance

Anti-skid surface

High demand in villas & resorts

Rubber moulds allow deep textures without surface defects.

🔷 3. Dual-Use Interlock Tiles (Indoor + Outdoor)

2026 sees rising demand for multi-purpose interlock designs that work for:

Parking areas

Garden pathways

Factory flooring

Outdoor patios

These designs reduce inventory complexity for manufacturers.

🔷 4. Compact Interlock Designs for High Coverage

Smaller interlock formats (200×200 mm, 250×250 mm) are trending due to:

Higher coverage per sq.ft

Easier transport & handling

Cost-effective production

Perfect for mass housing and export markets.

Advantages of Rubber Moulds for Interlock Designs

Rubber moulds are the backbone of modern interlock manufacturing in 2026.

✅ Key Benefits:

Long mould life (high ROI)

Sharp edges & uniform thickness

Easy demoulding with minimal breakage

Suitable for manual & hydraulic presses

Consistent finish across large batches

This makes rubber moulds ideal for new model interlock designs targeting export and premium markets.

Standard Sizes Used in 2026 Interlock Designs

| Size (mm) | Application |

|---|---|

| 200 × 200 | High-volume paving |

| 250 × 250 | Driveways & sidewalks |

| 300 × 300 | Commercial flooring |

Manufacturers prefer moulds optimized for maximum coverage per square meter.

Global Demand for New Interlock Designs

In 2026, demand for interlock paver moulds is growing strongly in:

Infrastructure projects

Smart city developments

Residential landscaping

Export markets in Africa, Middle East & Asia

Modern designs directly influence sales velocity and project approvals.

Why Choose JR Rubber Industries for Interlock Moulds?

JR Rubber Industries is a trusted global supplier of:

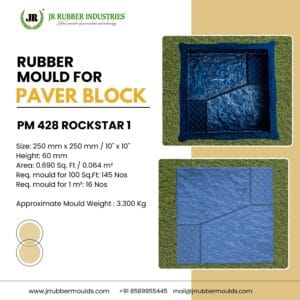

Rubber moulds for paver blocks

Floor tile rubber moulds

Interlock and designer paving moulds

🔹 What Sets Us Apart:

Precision-engineered mould designs

Export-grade rubber quality

Custom interlock design development

Proven durability & consistent results

New model interlock designs 2026 focus on aesthetics, efficiency, and long-term durability. With advanced rubber mould technology, manufacturers can stay ahead of market trends while delivering premium-quality paver blocks.

If you’re planning to upgrade your product range in 2026, investing in modern interlock rubber mould designs is the smartest move.