Top 5 Kerb Stone Mould Designs For Stylish Pathways

Kerb stones are an integral part of any outdoor area. They not only serve the necessary function of defining the boundaries of paths, roads, and driveways, but they can also enhance their overall appearance when designing curbstones. The shape of the mould plays an important part.

Kerb stone rubber moulds are utilized to form and shape the concrete material into curb stone’s desired dimensions, shape, and texture. They come in a variety of styles, each with its own attributes and advantages. This article will explore the different kinds of curb stone mould designs and their importance to the field of construction.

Understanding Kerb Stone Moulds

Kerb stone moulds ensure accuracy and consistency in the size, shape, and dimensions of the curb stones produced. This is important to achieve uniformity in the finished product, especially in large-scale projects requiring multiple curb stones. Kerb stone moulds are pliable enough to enable manufacturers to produce curb stones in various sizes, shapes, and designs to suit the specific needs of a project. This means that the aesthetic and functional needs of architects, landscapers, or contractors can be achieved.

The production methodology for curb stones helps develope improved in productivity measures. Moulds allow for easy and quick casting of curb stones within a short period, helping to reach the production target and project deadlines. They ensure the durability and quality of the finished curb stones. High-quality moulds are designed for lasting success in precast concrete, making the resulting curb stones solid and durable.

Rubber moulds’ flexible nature easily facilitates the separation of newly made curb stones from the moulds and prevents damage to the moulds or products. These rubber moulds are tough and abrasion-resistant, thus making them ideal for long-term concrete pouring. In addition, they can be an affordable, economical way of handling the production of Kerb stone products. Another common way to get Kerb stones is to use plastic moulds. Among other advantages of such plastic moulds, lightweight structures for making Kerb stones may enable them to be handled quickly.

Plastic moulds are very durable and withstand wear and tear well, providing reliable performance in several casting cycles. This material is also versatile, as it comes in various shapes and sizes, so one can make anything designed for Kerb stone production.

The metal moulds can withstand the most moderate concrete casting process and lengthy operations without experiencing deformation. These steel moulds offer excellent accuracy and precision in dimensions, assuring a consistent outcome in Kerb stone production. Although costly initially, long-term usage and durability of such moulds provide their cost-effective nature. Some of the composite moulds could strike a balance between toughness, flexibility, and durability, hence tending to be utilized in such particular applications as well as conditions of service. These moulds can provide tailor-made solutions for different project needs, thus making customized solutions for varying applications and environments.

Top 5 Kerb Stone Mould Designs By JR Rubber Industries

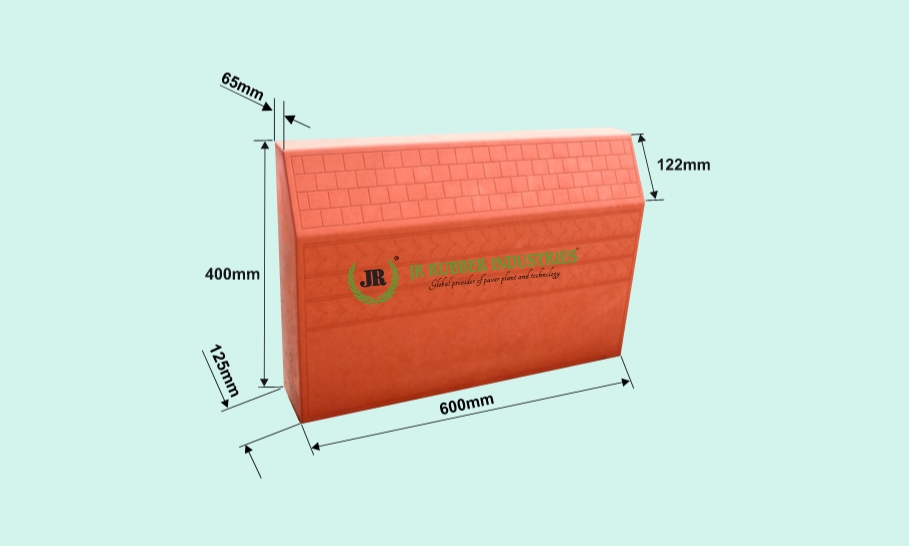

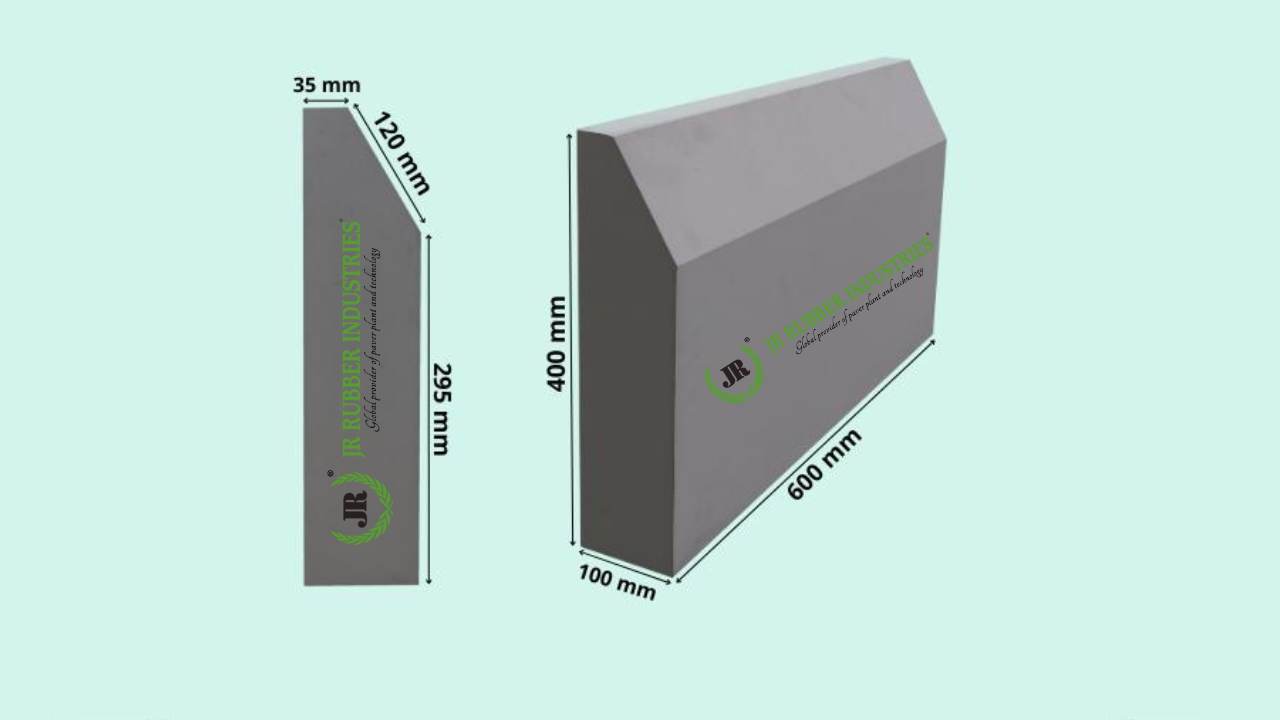

1. C5 Kerb Stone Rubber Moulds

C5 kerb stone moulds are constructed from premium rubber and designed to make durable and premium Kerb stones for different construction projects. These moulds reproduce natural stones’ appearance and texture, making the final product appear accurate and appealing. They are available in various shapes, including straight or curved designs, allowing infinite designs.

The process of manufacturing C5 Kerb Stone rubber mould design involves pouring the rubber into a designed mould and allowing it to harden or cure. When the mold is completed, multiple kerb stones with identical dimensions and designs can be made. This method of manufacturing is efficient, cost-effective, and reliable, making it the preferred option in construction work.

One of the main benefits of using C5 kerb stone rubber moulds is their flexibility. The moulds can be adapted to meet the project’s particular needs, allowing for the development of custom-designed and unique Kerb stones. They also have an even and non-porous surface, making it simple to leave the finished product without causing any damage or distortion. They are also lightweight and can be transported to various locations for construction.

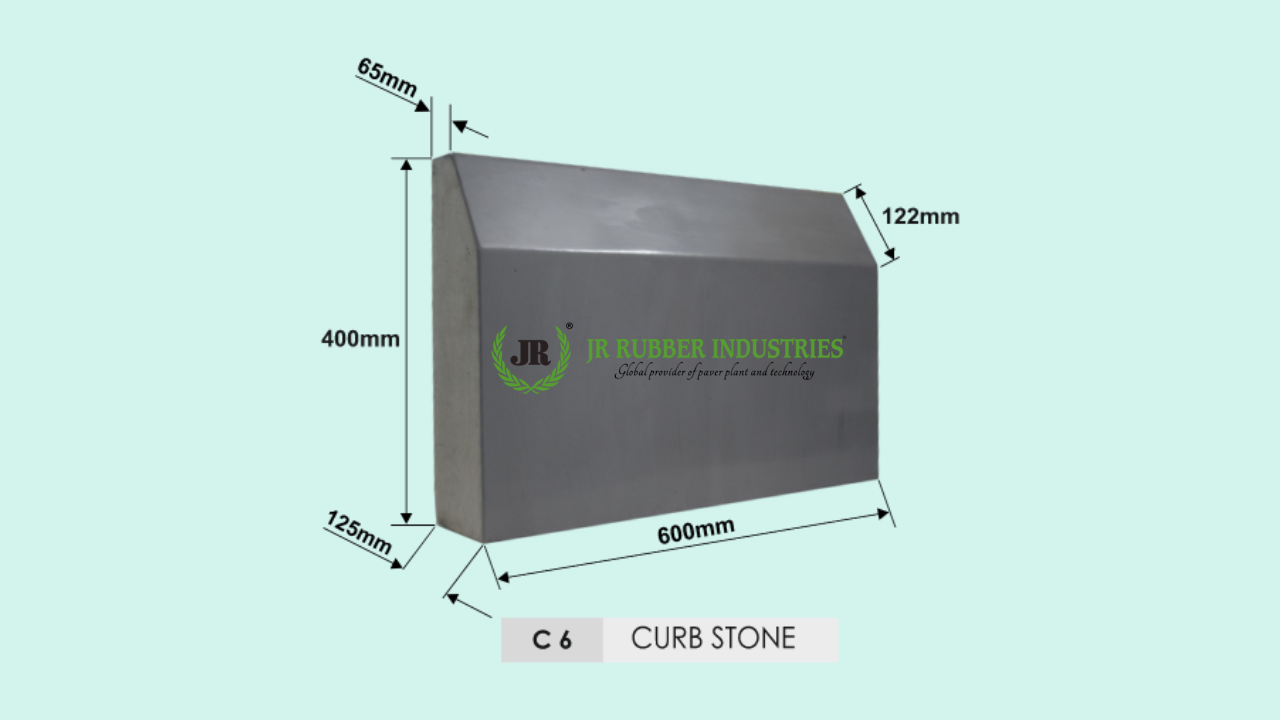

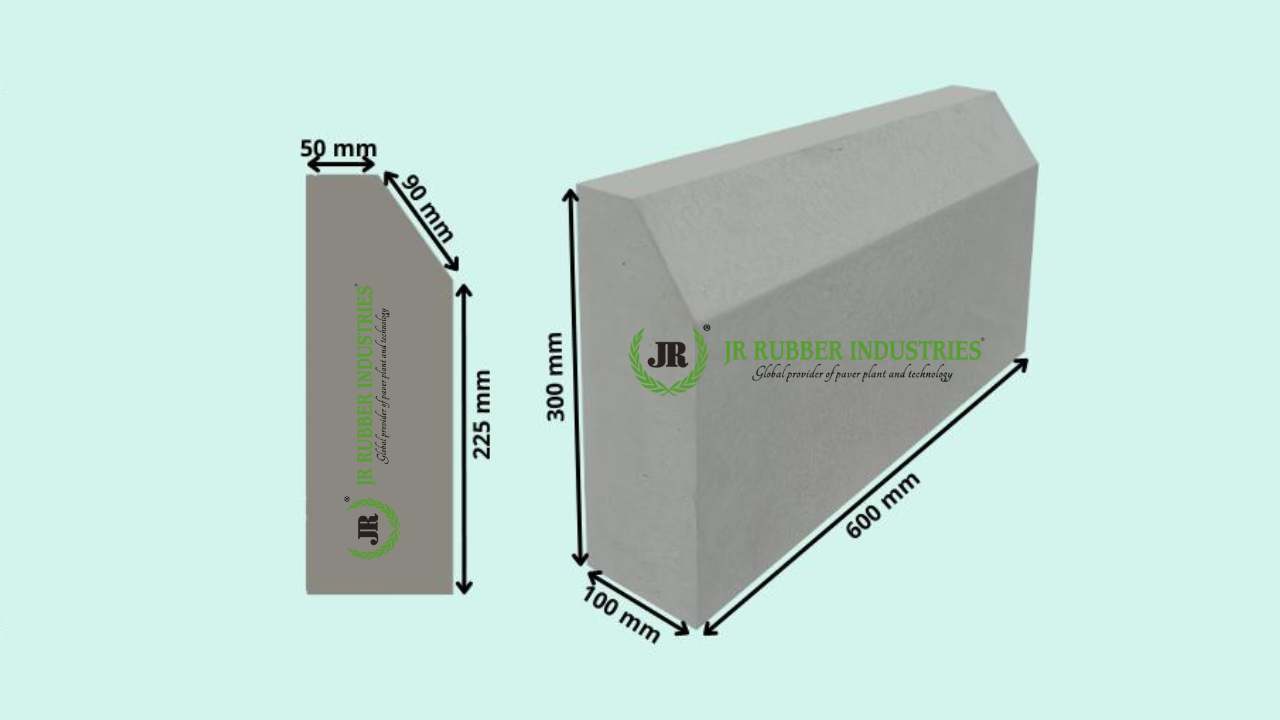

2. C6 Curb Stone Mould

The word “C6” might suggest a particular shape, body, or thing consisting of this stone, but we still do not have enough data to take for granted that it has the specified features mentioned in the word. To be exact, the stone is produced by the mason in different sizes for the various required mixtures that meet the design requirements along with the specifications of the designer or contractor. This could be concrete, stone, or any of the best-resistant materials.

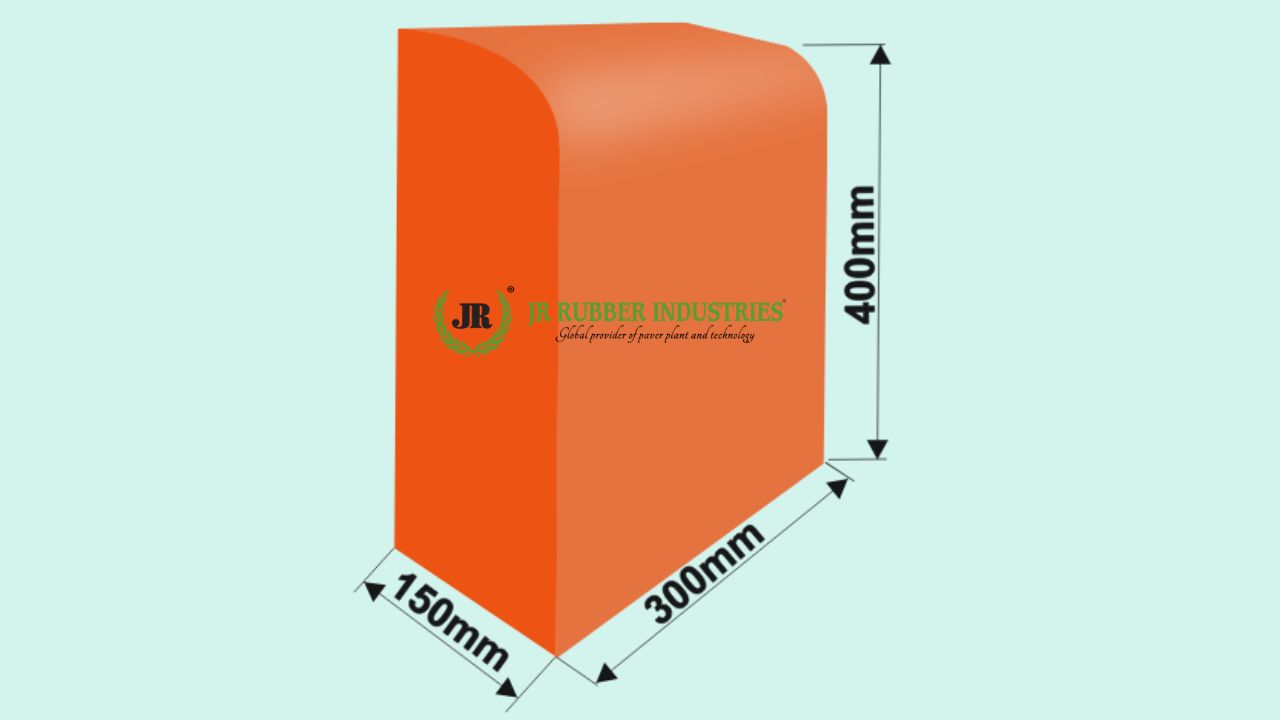

3. C7 Curb Stone Mould

4. C16 Curb Stone Mould

5. C17 Curb Stone Mould

Customization Option And Flexibility

Customers can customize the size and shape of the kerbstone mold according to their specific project requirements. Such biodiversity might display different levels, width, span, and arc measurements. Clients can choose different surface textures for the kerbstone molds. Such choices as smooth, textured, or even with the distinct pattern will be additional options for decorative motives. Depending on the intended use and environmental conditions, customers might request additional durability features for the kerbstone molds. Here it can be introduction of reinforcement methods or coating specials for the ward, weather or chemical resistance enhancement.

When we considering customization options for kerbstone mold designs from JR Rubber Industries or any other manufacturer, customers must communicate their specific needs and preferences to ensure that the final product meets their expectations. Furthermore, operators should double-check for extra charges or any shipments after individualized design requests to be properly prepared.

Texture is a crucial aspect that distinguishes curb stones’ aesthetic and performance mechanisms. Customers can select various texture options to achieve the desired look and feel. Variation may involve smooth finishes for that sleek modern look, textured finishes for the safety and ease of foot traction, or even marks and studs to create the effect of natural stone or brick.

Patterns can add visual interest and distinction to curb stone designs. They are offered a variety of patterns and can, therefore, secure schemes that fit their taste and the adjustments of their current purposes. Patterns may include geometric designs, decorative motifs, or custom logos or branding elements for commercial projects.

Application Of Designs

Kerb Stone Mould Designs In Landscaping And Pathway Projects

- Pathway Edging

Kerb stones in pathway installation are visible in most landscape works. They provide a defined border between the pathway and adjacent areas, Helping to contain gravel and other surfacing materials within the designated path. A concrete step will improve the step’s image, prevent erosion, and help preserve a neat and organized landscape.

- Garden Borders

Kerb stones can create raised garden borders or flowerbed edging. Curb stones can be grown at the garden beds by creating a course that blocks the planting box from other spaces, such as the lawn or hardscape. This adds structure to the garden design and helps prevent soil erosion while visually delineating different landscape areas.

- Staircases And Steps

By designing the landscape project, you can use curb stones to create stairs, steps, or other climbing surfaces, providing a safe and long-lasting passage to different levels of your outdoor space. Whether used in conjunction with retaining walls or as standalone features, curb stone size steps offer a visually appealing and functional solution for navigating changes in elevation within the landscape.

- Driveway Borders

The curb stones can be used to mark out the driveway’s edges; this will automatically set apart the driveway surfaces’ edge from adjacent landscaped elements. This helps prevent vehicles from encroaching onto landscaped areas while adding structure and visual appeal to the driveway design.

- Public Spaces And Walkways

Urban landscape projects often use Curbing blocks to showcase pedestrians, plazas, or other public areas. They usually involve painting, typical ornaments, and even flowers. They help define the boundaries of these areas, guide pedestrian traffic, and enhance pedestrian safety and accessibility.

Appearance And Functionality Of Pathway Designs

- Straight-Edged Kerb Stones

- Appearance : Mainly made of straight-edged curb stones, which suit paths for a more stylish trend. They create crisp lines and defined borders, creating a sleek and polished aesthetic.

- Functionality: This feature splay stone wall gives stability and support to the path and remains adequately fixed up and not really structurally compromised. They help to contain gravel, mulch, or paving materials within the pathway, preventing spreading or displacement.

2. Curved Kerb Stones

- Appearance : Rounded sighting curbs give pathways flow and rhythm. They soften the edges and create a more organic and inviting feel, particularly in landscaped settings with flowing contours.

- Functionality: Installing a curved roadside curb stone can primarily assist pedestrians in being self-reliant when walking the lane. They also facilitate smooth transitions between different pathway sections, easily accommodating changes in direction or elevation.

3. Textured Kerb Stones

- Appearance : We can use curb stones with a few textures to add aesthetic value and tactile functions to walkways. They add depth and dimension to the landscape design, creating a dynamic and engaging environment.

- Functionality: These slatted faces contribute to the anti-skidding and sliding conditions, which are especially important in wet and slippery circumstances. Thus, they increase the safety of pedestrians using the zebra crossing. Additionally, the texture helps to conceal wear and tear, maintaining the pathway’s aesthetic appeal over time.

4. Patterned Kerb Stones

- Appearance : Gratefully painted curb stones open pathways to individuality and chances to be quirky. They can feature intricate designs, geometric patterns, or motifs inspired by nature, adding charm and character to the landscape.

- Functionality: Furthermore, in conjunction with their visual beauty, they can give a sense of guidance to pedestrians or trained eyes to show them how to navigate the route. They help to delineate the pathway and create visual interest, enhancing the overall navigation experience.

Conclusion

We concluded with curb moulds, which offering a good comprehensive understanding of their significance in construction projects. It elucidates various curb mould designs, highlighting their unique features and functionalities. From straight to radius and custom moulds, the post emphasizes the importance of flexibility and customization in meeting diverse project requirements.By elucidating curb moulds’ versatility and adaptability to different project specifications, the post provides valuable insights into optimizing construction processes and achieving desired outcomes efficiently.

Choosing high-quality curb stone mould designs from JR Rubber Industries is crucial for creating stylish and durable pathways. Our commitment to excellence in craftsmanship guarantees that each mould produces curb stones with uniformity in size, shape, and texture, resulting in pathways that exude elegance and longevity. Whether you envision a quaint cobblestone pathway or a sleek modern facade, their skilled artisans stand ready to transform your dreams into reality.