Concrete vibrating tables are an essential tool in the construction industry, playing a crucial role in enhancing the quality and strength of concrete products. By using vibration, these tables help to compact the concrete mixture, reducing air pockets and ensuring uniformity. In this comprehensive guide, we will discuss different types of Concrete vibrator tables, covering everything from their types and benefits to factors affecting strength of concrete and quality control.

Concrete is widely recognized for its remarkable strength and durability, making it a crucial component in construction projects. However, achieving optimal strength and durability requires meticulous attention to the compaction process. This is where concrete vibrating table play a pivotal role. By ensuring effective compaction, these tables enhance the quality of concrete work, leading to superior strength and durability.

Principles and Mechanisms behind Concrete Vibrating Tables

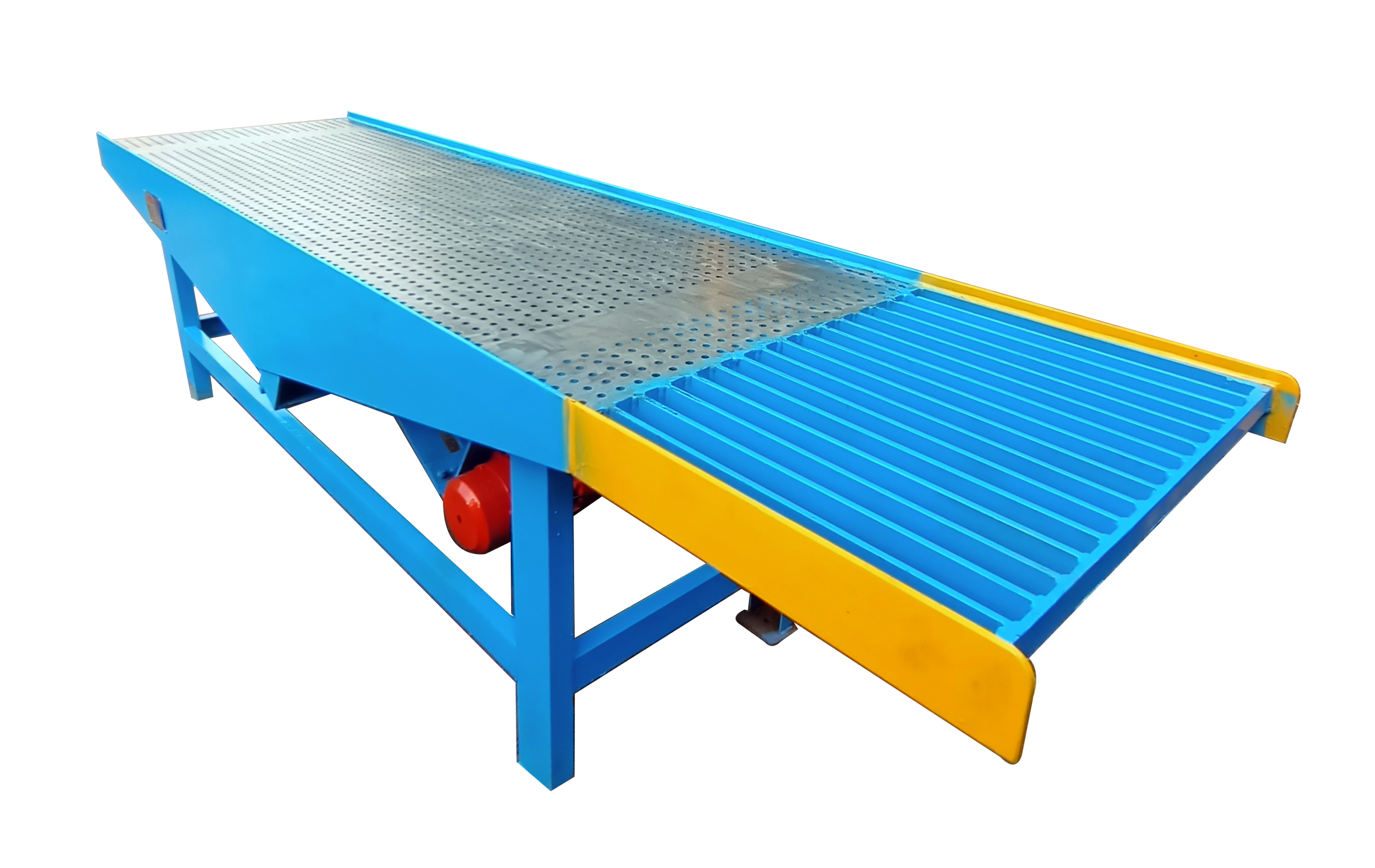

Vibratoring tables are machines which are used to vibrate concrete moulds or forms, allowing the mixture to settle and eliminate air bubbles trapped inside. There are different types of Table vibration machines such as internal vibrators, surface vibrators or external vibrators, and form vibrators. Surface vibrators are used for horizontal surfaces and internal vibrators are used for compacting concrete within forms. Form vibrators are specifically designed for vibrating concrete moulds. Understanding how these tables work is essential for their effective use.

By ensuring even distribution of the concrete vibrating tables promote improved strength and durability. This section will explore the scientific principles governing the compaction process and explain how vibrating tables leverage these principles for optimal results.

Exploring the Various Types and Designs of Vibrating Tables

The concrete industry offers a diverse range of vibrating tables, each designed to cater to specific project requirements. These tables vary in size, shape, vibration mechanism, and power source. From handheld units suitable for smaller projects to larger motorized tables for industrial applications, understanding the available options empowers you to select the ideal vibrating table for your unique needs.

Concrete Vibrating Table vibration machines offer several benefits. They can improve the concrete compaction, ensuring that the mixture is well distributed and densely packed. This helps the concrete product to attain strength and durability. In addition to this, vibrating tables help reduce the formation of air pockets and voids, resulting in a smoother and more uniform surface finish. These benefits make Concrete vibratoring tables indispensable in various applications, from precast concrete products to concrete countertop production and concrete block manufacturing.

Factors Affecting the Strength of Concrete

Several factors influence the strength of concrete. The proportion of the materials used in the concrete mix, especially the ratio of cement, aggregates, and water, plays a crucial role. Achieving the right balance is important for optimal strength. The water-cement ratio is one of the major factors. A higher water-cement ratio can weaken concrete and lower ration can result in a less workable mix. Proper curing techniques, such as maintaining moisture levels and temperature, also contribute to concrete strength. The properties of aggregates and the use of admixtures and additives can affect the final strength of concrete products.

Proper Operation and Maintenance of Concrete Vibratoring Tables

To ensure safe and effective use of concrete vibrating tables machines, it is crucial to follow proper operation and maintenance procedures. Safety precautions, such as wearing protective gear and ensuring a stable work surface, should be prioritised. Setting up the vibrating table correctly and adhering to operating procedures will help maximise its effectiveness. Regular maintenance, including cleaning and lubrication, will prolong the lifespan of the equipment and optimise its performance.

Common Challenges and Troubleshooting

While Table vibration machines offer numerous benefits, they can encounter challenges. Vibration irregularities, such as uneven distribution or excessive vibration, may occur and need to be addressed. Structural defects in concrete products can also arise, requiring troubleshooting to identify and rectify the underlying issues. Timely intervention and proper troubleshooting techniques will help overcome these challenges and maintain optimal performance.

Which is the best concrete vibrating tables manufacturer company in India?

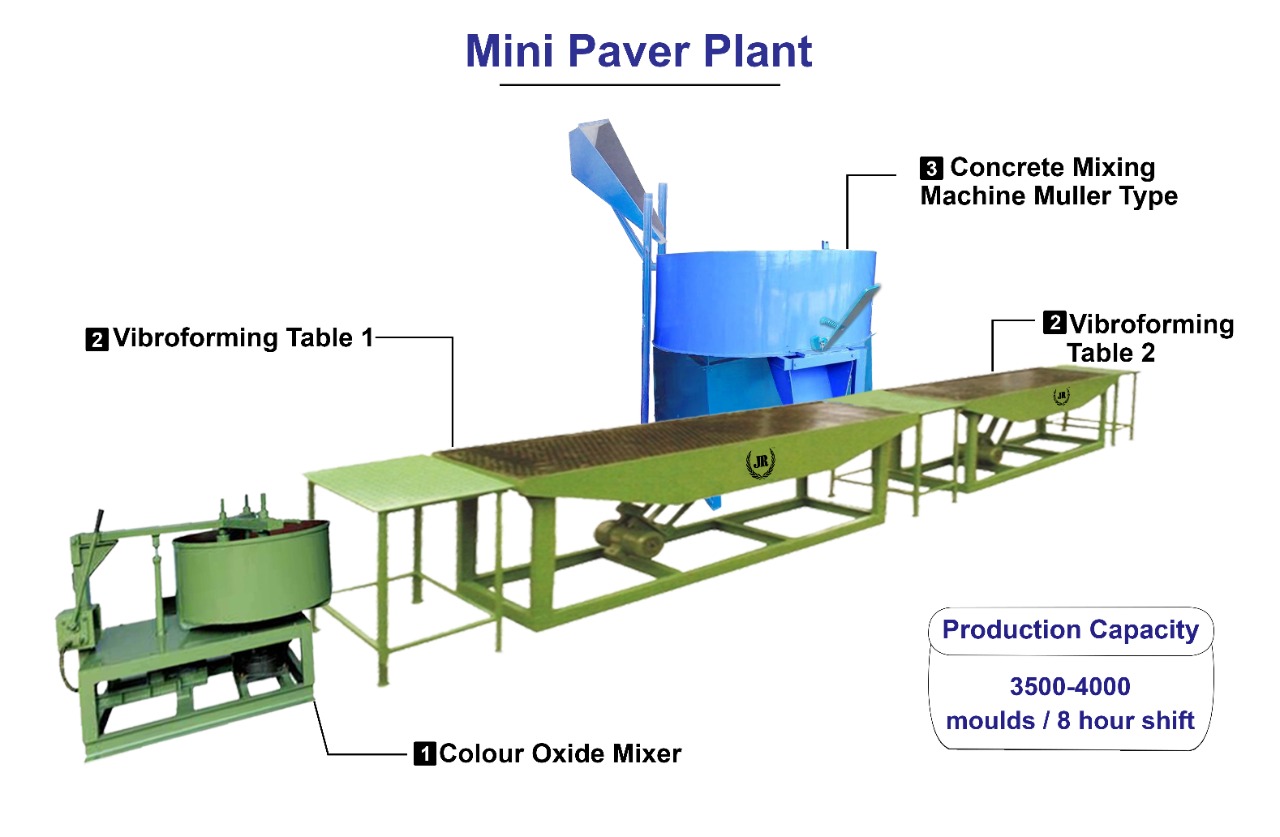

JR Rubber Industries manufactures Concrete vibrating tables. These vibrating tables are used in paver plants. We offer three different types of paver plants. Mini paver plant, semi-mechanised paver plant, and fully automatic paver plan. A mini paver plant consists of a Vibrating table and Semi-mechanised paver plant consists of four vibrating tables.

We offer high demanding concrete vibrating tables for quality concrete products. There were several factors affecting the strength of concrete products or paver block mold. We produce the best machines which can compete with all these factors.

The raw materials used to build the machine are of high quality and we ensure safety features also. Proper maintenance is necessary to ensure the productivity and safety of the machine. We have an experienced technical team to support you. We provide experienced services in Africa, Asia and GCC countries.

We are one of the leading producers of Rubber moulds, PVC moulds and plastic moulds and have service all the regions mentioned above.

Conclusion

Table concrete vibrating machines are indispensable tools for enhancing the quality and strength of concrete products. By consolidating the mixture and eliminating air pockets, these tables contribute to more robust and durable structures. Understanding the factors that affect concrete strength and selecting the right vibrating table for your project are essential steps in achieving optimal results. Proper operation, chemical and color oxides mixing, maintenance, and adherence to quality control measures ensure consistent and reliable concrete products.

FAQ

Can a vibrating table improve the strength of concrete?

Yes, by eliminating air pockets and ensuring uniform compaction, a vibrating table enhances the strength and durability of concrete.

What is the purpose of a Table vibration machine ?

A Concrete vibrator table is used to consolidate and compact concrete, reducing air pockets and improving its strength and durability.

What are the factors that affect the strength of concrete?

Factors such as the proportion of concrete mix, water-cement ratio, curing process, aggregate properties, and the use of admixtures and additives influence the strength of concrete.

Are there any maintenance requirements for Table vibration machines?

Yes, regular cleaning and lubrication are necessary for maintaining the performance and longevity of concrete vibrating tables.

How do I choose the right concrete vibrator for my project?

Consider the specific application, table size and capacity, vibrating mechanism and power source, and additional features and accessories to select the appropriate Table vibration machine .