Elevate Your Property with the Best Compound Wall Design of 2024: Unveiling Innovations with JR Rubber Industries

Precast boundary wall design is the construction of a wall used to mark an area’s boundaries. This includes delineating the goal of the wall’s Design, choosing suitable materials, and determining the wall’s appearance. In addition, the layout should be able to consider other factors, like the environment and regulations, if there are any. The primary purpose of creating a boundary wall is to increase security. The beauty of a boundary can significantly enhance the house’s overall appearance.

JR Rubber Industries manufactures Rubber moulds to make precast compound walls in various styles and sizes. We make Rubber moulds for precast boundary wall panels, poles, and copping moulds. We also make rubber moulds to be used as boundary wall base moulds, which are needed for every element in a compound wall.

Top Trends in Compound Wall Design

Compound wall designs are evolving to reflect the latest trends in architecture and landscaping. Modern compound wall designs combine functionality and aesthetics by creatively incorporating concrete, metal, stone, or other materials. Eco-friendly solutions that are visually appealing include green walls with integrated lighting. Individualization is achieved through texture, pattern, or even digital elements.

1. DS 100 Classic Design

The DS 100 Classic is the best compound wall design for residential and commercial areas. The numerous squares give the wall a unique and trendy look. Its timeless elegance in construction and architecture makes it the preferred Design for many projects.

One of the DS 100 Classic’s most essential characteristics is its versatility and ability to seamlessly blend in with various architectural styles. Standardized brick measurements provide uniformity during installation and ensure accuracy, resulting in an attractive and polished appearance. The DS 100 Classic is a versatile compound wall design that can create precast boundary walls, landscape projects, or facades.

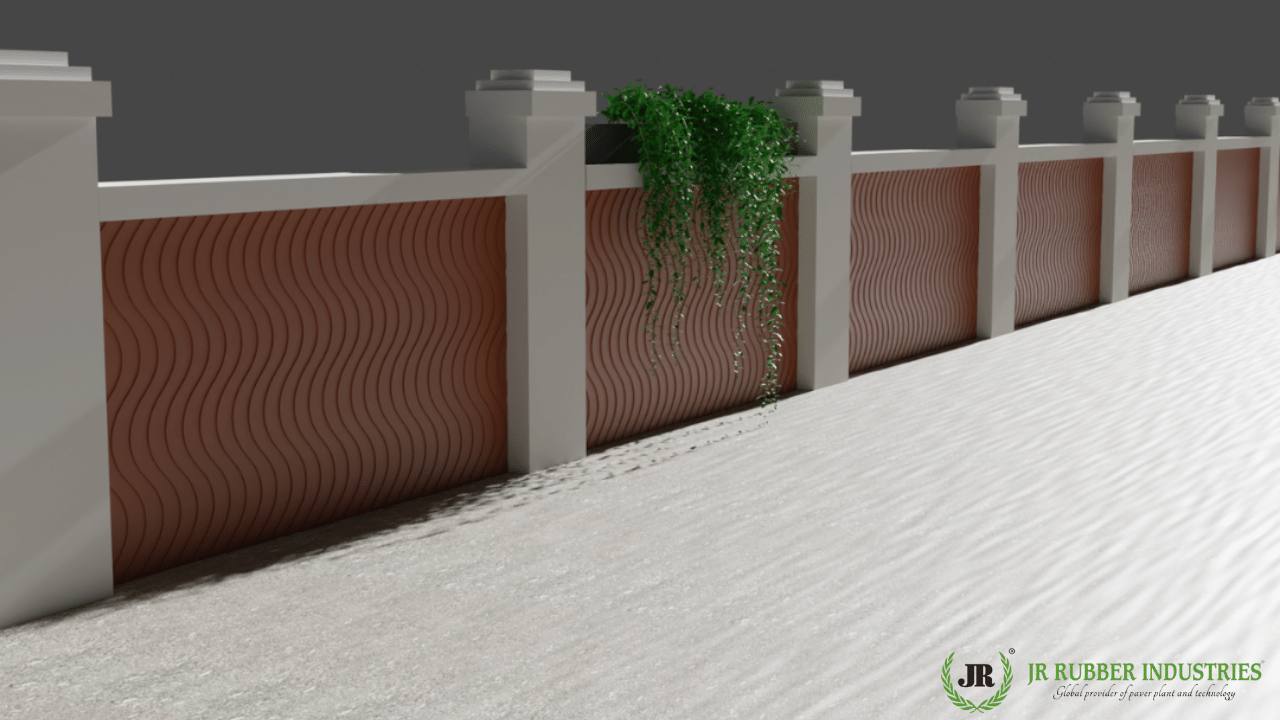

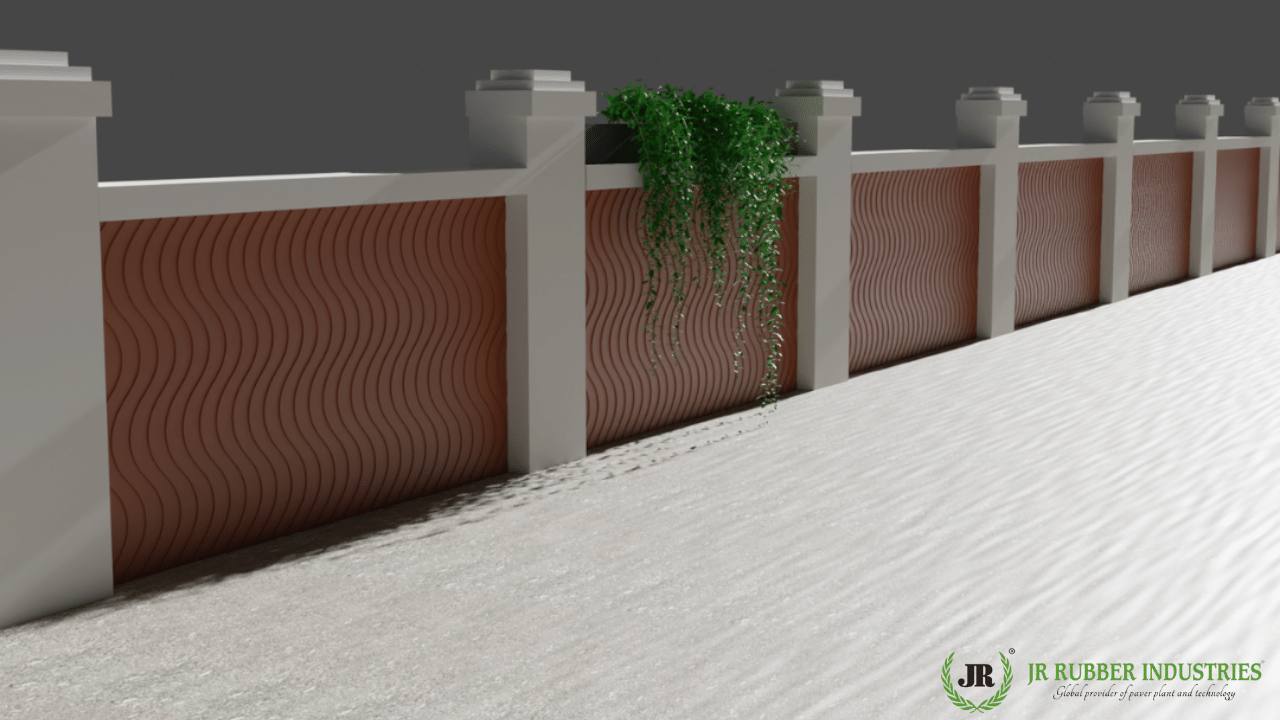

2. DS 101 Tide Wave Design

DS 101 Tide Wave is a unique and attractive option for improving the appearance of residential and commercial properties. The wave-like pattern makes this compound wall modern, dynamic, and different from other designs.

The Tide Wave Design of the building is defined by flowing, undulating lines reminiscent of ocean waves and other natural elements. Its unique Design creates an atmosphere of vitality and motion in the area, which makes it a focal point for architectural curiosity.

The DS 101 Tide Wave Compound Wall design combines creativity with practical excellence. It is the choice of those who want a modern and distinct look for their boundaries.

3. DS 102 Brick Design

This compound wall Design, known for its aesthetics and structural strength, has become a popular choice for precast walls. The DS 102 Brick design is a new approach to compound wall construction. Before considering implementation, it is essential to evaluate the structural aspect of this Design to ensure its safety and feasibility. The Design must be checked to meet all the necessary height, stability, and thickness standards. It is also essential to check that the brick arrangement contributes to the overall strength of the wall.

By carefully evaluating these factors, we can ensure the reliability of the DS 102 brick design. The sturdy Design improves the security of the compound walls and gives them an attractive appearance that seamlessly blends in with the surroundings.

4.PP 204 Urban Fence Design

PP 204 Urban Fence design gives, readymade compound walls a contemporary feel. Thoroughly assess the structure and safety requirements. The items should be arranged and spaced so they remain stable.

We have carefully analyzed the factors of urban fence design and can confirm that it is a robust compound wall system with a pleasing visual aesthetic.

5. DS Hi Wall Design

DS hi-wall Design is an elevated wall, usually taller than the standard wall. These walls can provide privacy and security. Precast concrete panels are used to make these walls. They can resist increased heights and lateral forces.

Several features ensure the structural integrity of high wall panels. These panels are reinforced with fibres or steel bars to increase their strength. When exposed to external forces or weight, the panels are not prone to cracking. The foundations of these walls are usually broader and deeper than those of standard walls. Foundations provide support and stability

Innovations in Compound Wall Design Patterns

Compound wall designs have recently seen increased creativeness, flexibility, and customizability options. This is in response to the changing needs of property security and aesthetics. New patterns combine artistic features with practical elements, reinventing traditional barriers. Materials like wood, concrete, metal and glass are combined to create designs that offer a variety of finishes and textures for architectural styles.

Height, thickness, and security features such as integrated lighting or intelligent surveillance systems can be customized. compound wall design Pattern such as geometric motifs or textures inspired by nature enhance visual appeal. Abstract forms and shapes are also attractive. The beautiful designs offer tailored security, essential in the modern landscape.

These innovations reflect a paradigm shift toward integrating form and function into compound walls, ultimately elevating the property experience.

Role of JR Rubber Industries in Compound Wall Design

As India’s leading compound wall manufacturer, we are pleased to announce our presence. Over the last 29 years, we have become the leading compound wall manufacturer nationally and internationally. JR Rubber Industries, a leader in manufacturing precast composite walls, is located at JR Rubber Industries.

JR Rubber Industries produces Rubber moulds in various sizes and designs for precast compound walls. Compound walls have all elements precast at the factory and then installed on-site. The Design and colours are pre-programmed. The rubber moulds can quickly be demolished and are flexible, ensuring the production is not damaged. There are moulds in different designs, textures, and perforations that can only be cast using Rubber moulds.

Glossy, unmatched finish for precast wall boundary cast in rubber moulds. Vibro-formed moulds are used to form concrete. This gives concrete products a high level of strength. To improve the stability of panels, glass fibre and reinforcements can be added to the admixture.

Product Offerings from JR Rubber Industries

We offer a wide range of products, including precast compound walls, RCc boundaries, moulds for compound walls, and wall panels. Precast walls are cheaper than stone or brick walls, and precasting allows for beautiful designs that are impossible with brickwork or stonework.

Precast walls are quick to install and save on labour costs. We will install them for you. Compound walls can also be very sturdy. Our products are easy to cast. High-strength concrete panels can be cast, and stunning designs are available.

Conclusion

Recent developments in the precast compound wall design highlight the need for high-quality products to enhance the aesthetics and safety of properties. These designs combine creativity, flexibility, and customizability to improve a home’s aesthetic appeal and meet evolving security requirements.

Developers and property owners should consider these new solutions when planning projects. Well-designed compound walls not only increase the property’s value but also improve the experience for residents and guests.

JR Rubber Industries is a notable supplier of high-quality compound wall products. we are known in the industry for their dedication to innovation and excellence. JR Rubber Industries’ customizable designs, quality materials and emphasis on security make them the preferred choice for all projects.