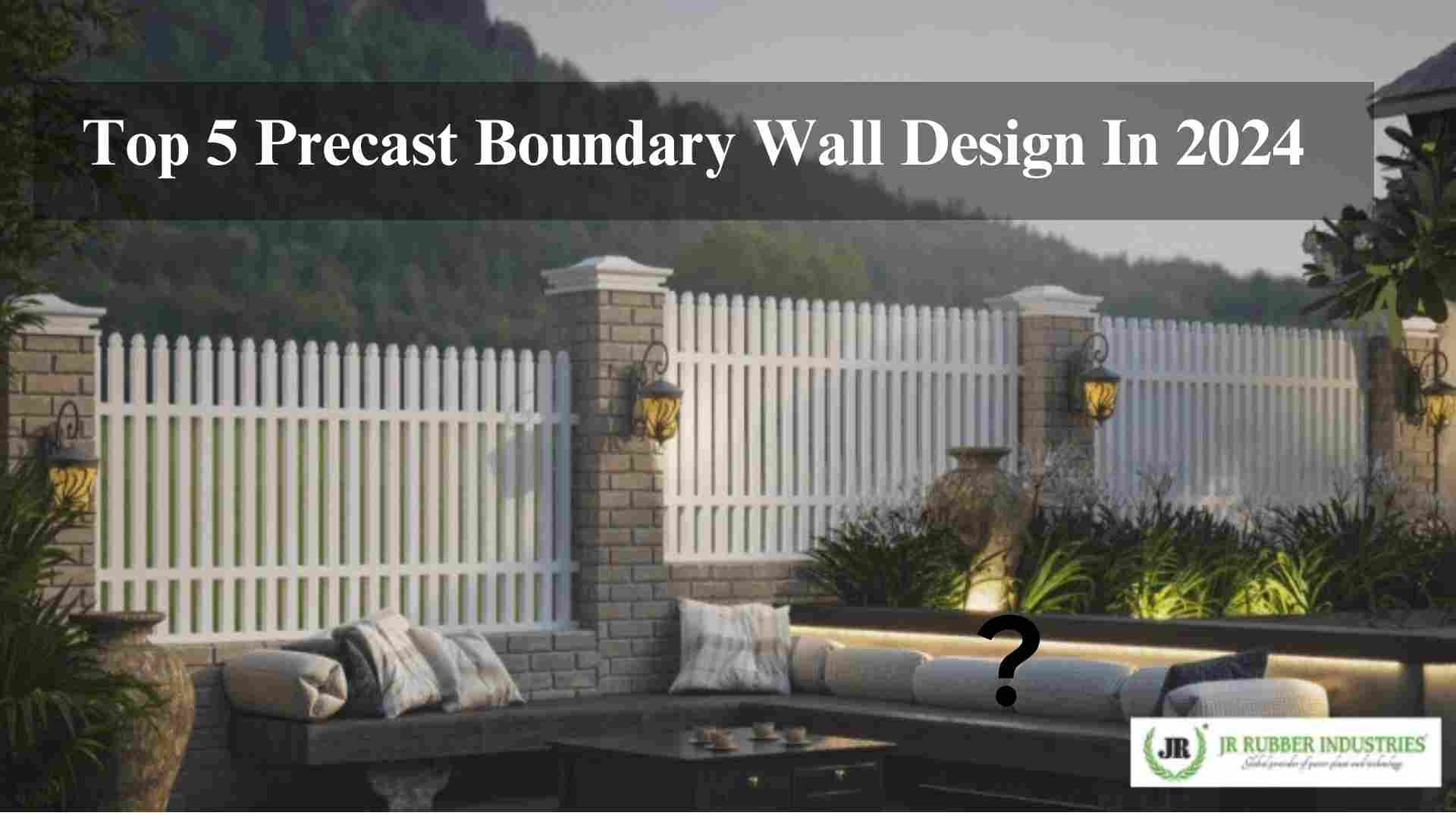

Top 5 Precast Boundary Wall Design In 2024

Here, we are dedicated to exploring the top 5 precast boundary wall design in 2024 by JR Rubber Industries. A boundary wall or fence is more than just an aesthetic choice. It’s an important feature that offers security, privacy, and property delineation. It is a physical barrier that enhances the safety and privacy of your property. Cost-effective precast wall options are available for the construction of boundary walls. Often, precast walls are made in factories and transported on site where they can be installed easily and quickly. This blog also shows you how to choose the perfect precast boundary wall design. Let’s explore the top 5 precast boundary wall design in 2024.

What Is A Precast Boundary Wall?

Precast boundary wall is a type of fencing or barrier constructed using precast concrete panels. These panels are manufactured off-site in a controlled environment, ensuring high quality and consistency. Once produced, they are transported to the construction site and installed to create a boundary around a property.

The precast wall is widely recognized as an efficient and durable building method. The concrete panels are manufactured in a controlled atmosphere and then assembled on-site.

The Benefits Of Precast Boundary Wall Design

- Quick Installation

Precast walls are becoming more popular. When you’re working on a big project, speed becomes a necessity. Precast boundary walls are time-saving because they are installed on the construction site. All that’s required is correct assembly.

- Durability

Precast constructions can also be used to create a modular wall. A precast structure can be modified, enlarged or removed. They are made from high-tensile steel reinforced concrete and high-grade cement, so they last very long. The wall textures are also perfect.

- Customization

The aesthetics of precast wall boundaries can be customised. The appearance of buildings can be improved by using precast concrete in various ways. The precast concrete wall can be used for many different purposes. These are also less expensive, easier to maintain, and resistant to weather, fire and termites.

How Are Precast Boundary Walls Made?

Precast boundary walls are made from concrete extrusion machines and reinforced with carbon steel wires. The machines don’t require moulds or form work.

Concrete is cast in moulds that can be reused and dried in controlled conditions. The precast panels are then transported to the construction site and placed in place. Precast walls are designed to speed up construction and maintain high standards. We will explore the different aspects of precast walls.

The Precast Concrete Manufacturing Process

To fully understand the construction process of precast concrete walls, it is essential to explore the manufacturing process.

1. Concrete Mixture Preparation

The manufacturing process begins with setting the structural requirements for the precast concrete components. Design engineers calculate the necessary specifications, and the mixture for precast concrete is created by combining water, cement, and fine and coarse aggregates. This mixture is carefully formulated to meet the project’s durability, efficiency, and aesthetic requirements.

2. Mould preparation

Once the production plan is ready, raw materials are selected and delivered to the mould factory. moulds using only strong high-quality steel with excellent surface finish.After the raw materials are received, inspected and documented, the actual production begins.A critical stage in making table moulds is welding the frame on which the top steel surface is attached.Each precast boundary wall design mould is inspected at least twice by using optical measurement instruments.Once attached to the frame, the steel surface is evened out using a very precise digitally controlled and fully automated grinding machine. A final check is done to each precast boundary wall mould before rust protection treatment

3. Pouring Concrete In To Moulds

After the concrete mixture is produced, it undergoes several tests, including a spread test to ensure proper flow and absence of aggregate segregation. Once the mixture passes the tests, it is poured into precast boundary wall mould.Many precast plants use batching machines controlled by computers to ensure exact and consistent concrete placement.

4. Curing

For optimal density and strength to maximize strength and density, concrete is compressed using high-frequency external vibrators or pokers. The process of compaction makes sure that concrete remains free from bubbles and air pockets. After being compacted, the precast units are dried in a controlled atmosphere to ensure the maximum strength and sturdiness.

5. Demoulding

For optimal density and strength to maximize strength and density, concrete is compressed using high-frequency external vibrators or pokers. The process of compaction makes sure that concrete remains free from bubbles and air pockets. After being compacted, the precast units are dried in a controlled atmosphere to ensure the maximum strength and sturdiness.

6. Finishing Process

Exterior finishes, such as painting, staining, or sandblasting, are applied, while joints are caulked to prevent water penetration.At this stage the roof system is also installed. With the structural framework in place, interior work, such as electrical and plumbing installations, can commence.

Top 5 Precast Boundary Wall Designs By JR Rubber Industries

1. DS Classic Design

DS Classic design is an iconic design that can be found for commercial and residential locations. Numerous small squares of this wall give a classy look to our surroundings. The numerous small squares of the compound wall designs mould are unique from all others.

2. DS Brick Design

The DS brick design is one of the most popular designs frequently used in residential zones and commercial areas to safeguard our homes. The DS brick designed boundary wall features a brick-shaped shape. We were unable to recognize the wall made of brick since it’s similar to the walls constructed from regular brick. It makes the brick design more desirable than other wall designs.

3. Urban Fence Design

Urban Fence Design is a modern boundary wall design for aesthetics and functionality. These designs are often characterized by a sleek, modern look that offers security and privacy. Precast panels are used to create DS Urban Fence Designs. They feature clean lines, minimalistic detailing, and a variety of surface textures or patterns that add visual interest.

The design can include horizontal or vertical slats or geometric patterns or alternating textures for a dynamic, visually pleasing look. DS Urban Fence Design may include decorative elements, such as planters or integrated lighting to enhance the overall aesthetic.

4. DS Tide Wave Design

DS Tide wave design is innovative and impressive by JR precast compound walls. The DS Tide wave precast compound wall mould is designed in a wave shape, giving our house or our plot an entirely different look.The wave-shaped precast compound wall design is constructed from cement by using moulds made of rubber for making the precast wall. That gives the wall an excellent finish, sturdy and durable.

5.DS Hi Wall Design

Ds hi wall design is a high wall that is typically taller than standard ones. They can be used for privacy or security. These walls are usually made of precast concrete panels that can withstand increased heights as well as lateral forces.

Customization And Flexibility Option Design For Precast Concrete Wall

1. Customization

Customization options for precast concrete walls give architects, engineers, and builders a unique advantage. This allows for the creation of custom designs to meet project requirements while still allowing flexibility in design.

The versatility of precast concrete is one of its most important benefits. The precast concrete walls can be customized to meet any requirements. It is possible to create walls with irregular or curved shapes and heights. Designers can control the appearance and functionality of structures with this flexibility.

The flexibility of precast concrete walls and the customization options available to designers and builders offer many benefits. Options allow unique, personalized designs while providing functional and sustainable solutions for project needs. Precast concrete is a versatile material with many applications in the construction industry.

2. Design Flexibility

The design flexibility of precast concrete walls is a huge advantage. Precast concrete walls offer architects and designers the flexibility to design unique structures that are versatile and flexible while still taking advantage of the precast advantages.

Precast concrete walls offer a great deal of design flexibility, including a variety of customizations, easy installation, and structural flexibility. This allows designers and architects to create visions while ensuring durability and quality.

How To Choose Right Design For Precast Boundary Wall

Choosing the Right Design for precast boundary wall design is crucial in protecting concrete from mould growth, so it’s not surprising that we always choose quality materials with this aim in mind. The choice of post-cabinet construction also helps ensure adequate protection when wetting and washing down walls. These products have less impact on structural integrity than typical castwall building methods. There are several advantages to using prefabricated panels, including greater rigidity compared to traditional panel systems because they’re made relatively inexpensively.

Conclusion

JR Rubber Industries is exploring the top 5 precast boundary wall designs. Precast walls offer security, privacy, and property delineation, being cost-effective and easy to install. They are durable, have a smooth finish, and can be customized. Made from high-grade materials, precast walls are quick to install and resistant to fire, termites, and weather. The manufacturing process involves concrete extrusion machines and steel reinforcement, without the need for moulds.Precast concrete walls offer versatility in size, shape, and texture, allowing for unique designs tailored to project needs. Choosing the right design is crucial for mould resistance, with precast walls offering durable and high-quality solutions. Prefabricated panels also offer advantages in rigidity and cost-effectiveness compared to traditional building methods.

Selecting high-quality precast boundary wall designs from JR Rubber Industries is paramount for ensuring the durability, reliability, and aesthetic appeal of your construction project. JR Rubber Industries is renowned for its commitment to excellence in manufacturing precast products, utilizing advanced techniques and premium materials to deliver superior results. By opting for their boundary wall designs, you can benefit from precision engineering, stringent quality control measures, and innovative customization options tailored to your specific needs.

JR Rubber Industries offers a variety of precast wall styles tailored to meet a variety of aesthetic and practical needs. From modern to classic styles, look through their catalogue to find the right solution for your particular project. Additionally, their customizable options allow you to customize the boundaries of your walls, ensuring they are seamlessly integrated with your architectural plan. You can trust JR Rubber Industries to transform your concepts into reality and push the boundaries of possibilities in construction.