Best Cover Block Mould In Nepal

Cover block mould in Nepal is an innovative alternative to more conventional options, made from high-grade rubber material with excellent flexibility and resilience. Cover blockn mould is commonly utilized in applications requiring vibration isolation such as sound-sensitive areas or structures housing heavy machinery; their soft rubber surface absorbs impacts while simultaneously reducing noise transmission for an enjoyable and peaceful atmosphere.

Product Overview

Cover block rubber moulds are non-reactive and corrosion-resistant, offering long-term durability to construction projects. Due to their non-reactive nature, cover block molds make an excellent choice for supporting and maintaining spacing requirements between reinforcement bars in construction projects while helping reduce vibration transference, protecting structures from damage, and prolonging the lifespans of construction projects. Cover block moulds play an essential role in providing this vital service in support of reinforcement bars during support purposes of projects.

Types Of Cover Block Moulds

When it comes to selecting an effective design for concrete cover block moulds, there are various designs available that have already proven themselves effective. Here are a few such designs.

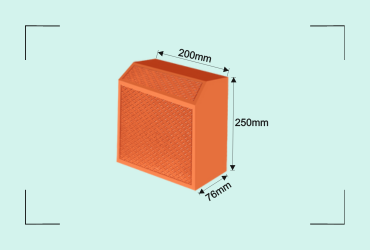

Cover Block 1

It was carefully designed to meet specific construction needs. Its distinctive shape and composition provide ideal reinforcement bars in columns and beams. In contrast, its high-grade concrete piece offers durability, strength, and load-bearing capacity, reinforcing structure integrity.

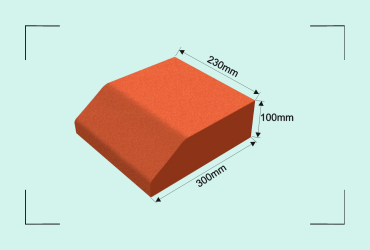

Cover Block 2

Cover Block 2 stands out with its versatility and adaptability, making it the ideal solution for residential buildings or commercial complexes. Thanks to its innovative design, Cover Block 2 allows builders and engineers to tailor its height and dimensions according to individual project’s specific requirements – perfect for construction projects of all kinds!

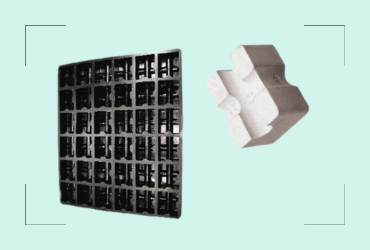

Cover Block 3

Cover Block 3 deserves special recognition for its innovative and robust nature. Crafted with an outstanding combination of concrete and additives, its strength and resilience make it ideal for heavy-duty construction projects.

Cover Block 4

Cover Block 4 stands out for its outstanding load-bearing capacity and stability, making it ideal for construction projects requiring major structural support. Engineered specifically to withstand heavy loads, its design lends itself well to supporting large-weight loads while remaining stable.

Cover Block 5

Versatility and ease of use make the cover block 5 the ideal tool to meet various construction needs, from residential buildings to infrastructure projects. As with other cover block molds, its benefits are unending!

Customer Testimonials

“JR Rubber Industries’ cover block molds were a smart choice for our project in Biratnagar. They are strong and easy to handle, making our construction work more efficient. JR Rubber Industries is reliable!”

“In Butwal, we relied on JR Rubber Industries’ Cover Block Moulds. They’re strong, and our structures look neat. JR Rubber Industries provides reliable and good-quality solutions.”

Why Choose JR Rubber Industries?

At our mould factory, all our moulds are constructed using virgin raw materials for maximum dimensional stability over time and long-term reliability. JR Rubber Industries is the world’s premier provider and seller of Rubber, Plastic, and PVC Paver Moulds for production, offering machinery, molds, chemicals, technology, and in-plant training to complete paver solutions. You will find various designs of paver molds to add beauty to specific areas or surfaces as customers request. With clients across India and 34 other countries worldwide and our experience establishing over 1500 paver units within India alone and over 68 production lines worldwide, JR Rubber Industries can find you the ideal molds to produce your paver production needs!

Installation support of Paver mold machines is offered, along with chemicals and color oxides necessary for making paver blocks. Our sales and support teams can ensure success for those starting their production firms; they’re here whenever needed!

Our Services

- Design, engineering, supply, and installation of machines

- supply of chemicals and color oxides

- Paver production assistance anywhere in the world

- In-plant training for client personal

- Onsite machinery fabrication and Installation anywhere

- Design and develop customized molds

How To Order

To order our Cover Block Mould in Nepal, you may visit our website, WhatsApp or click the Contact Us button below.

FAQ

1. Can I use Cover Block Moulds for both residential and commercial projects?

Yes, cover block molds are versatile and suitable for a wide range of projects, from residential buildings to commercial structures.

2. Can JR Rubber Industries customize Cover Block Moulds for unique project requirements?

Yes, JR Rubber Industries offers customization options to meet specific dimensions and project needs, ensuring tailored solutions.

3. Are JR Rubber Industries' Cover Block Moulds suitable for precast concrete applications?

Yes, JR Rubber Industries’ Cover Block Moulds are suitable for both in-situ concrete casting and precast concrete applications, offering versatility.

4. Can I get assistance from JR Rubber Industries in choosing the right size of Cover Block Moulds for my project?

Absolutely. JR Rubber Industries provides assistance in choosing the appropriate size of Cover Block Moulds based on project requirements and specifications.

5. Does JR Rubber Industries provide technical support for the installation of their Cover Block Moulds?

Yes, JR Rubber Industries often provides technical support and guidance for the proper installation and use of their Cover Block Moulds, ensuring optimal performance.