PAVER MOULDS: Designing the Face of a City in 2024

By JR Rubber Industries | Date : 19-July-2024

Home > Blog > Paver Moulds

Paver molds are crucial in construction to create beautiful and sturdy concrete pavers. The molds provide patterns, colors, and textures to concrete, or cement mix, resulting in beautiful and practical pavement stones.

Paver molds are available in various dimensions and shapes, allowing contractors to develop different unique styles to satisfy their designs’ individual needs and preferences. Paver molds are vital in turning plain concrete into appealing and practical surfaces for sidewalks or driveways, patios, and other outdoor areas.

Types of paver moulds

Paver molds provide the basis for creating intricate and attractive pavements. The molds are available in PVC mould, Rubber mould, or Plastic moulds. Concrete mix is poured in to moulds vibrated on vibroforming table. This gives pavers excellent finishing and streangth, it’s aollowed to cure for a day demoulded allowed to dry in shade then its ready to use. Thus construction experts can achieve uniform and precise results regardless of how intricate the design is.

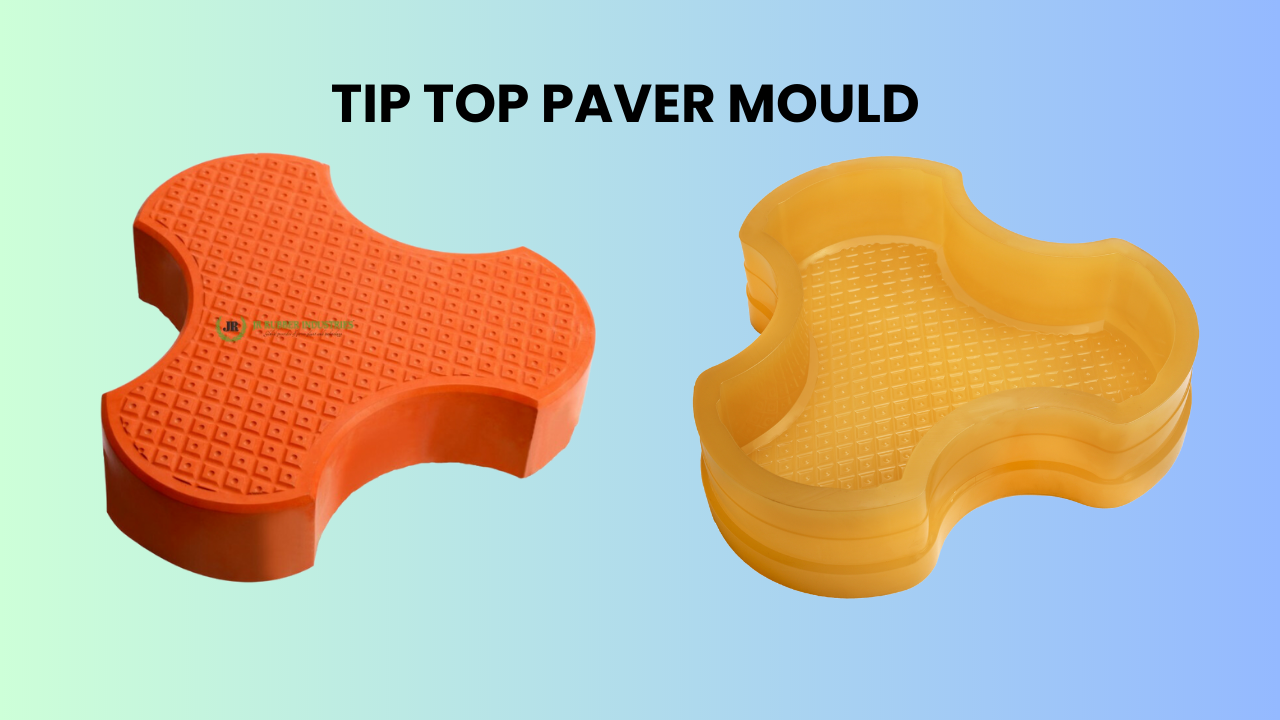

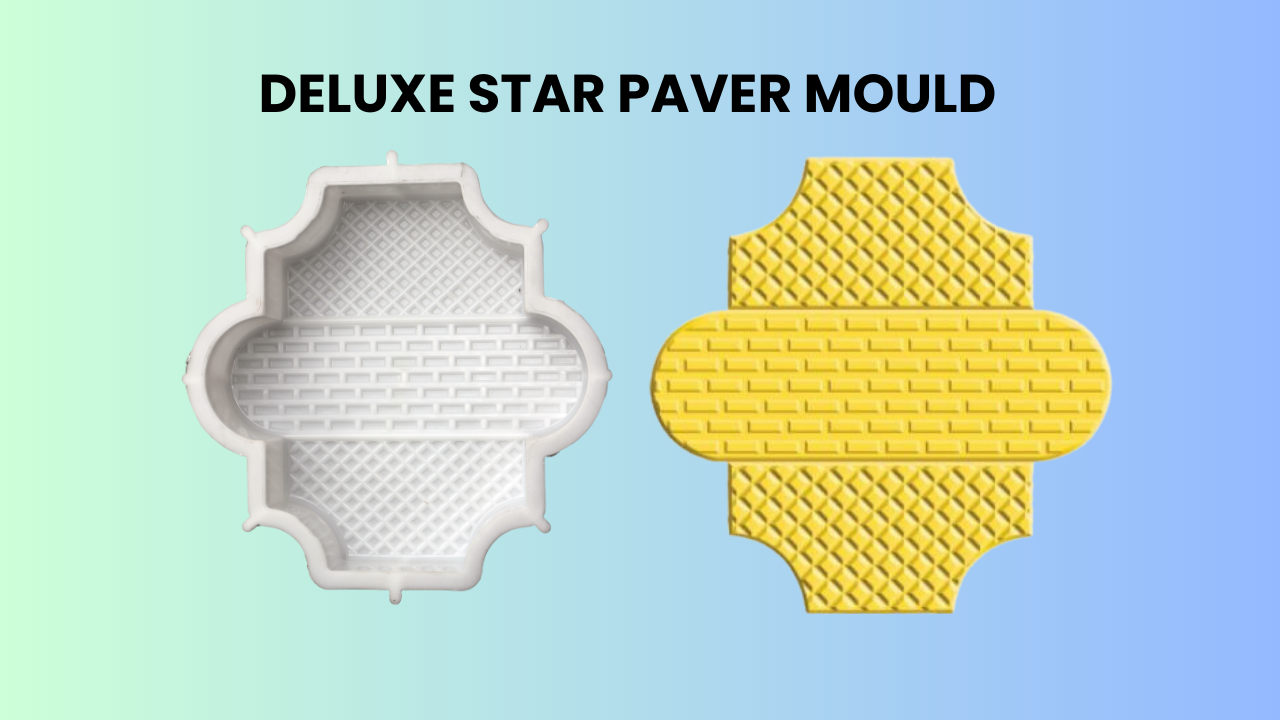

Rubber paver mould designs

Rubber paver moulds, also known as rubber mold bricks or tiles, are specially designed moulds used to produce rubber paver. These moulds are typically made from high-quality rubber raw materials, our state in Kerala, India is a largest producers of natural rubber. The intricate designs carved into these moulds allow for the creation of diverse paver patterns, adding a touch of elegance to any outdoor area.

Advantages of JR Rubber paver moulds

- High dimension stability.

- Rubber have long lifespan.

- Easy de-molding due to the non-sticky Coating of the Moulds.

- Smooth and Shiny surface for the Tiles and Paver Blocks .

- Any intrinsic patterns are effectively transfer to Stones due to the unique property of Rubber mold.

- Vibration of vibrator machine is transffered eficiently to the concrete mix which ensures optimum strength for the paver.

- Our customers when procuring moulds expect for a lifespan of 4-5 years. But across the globe our rubber moulds are used for more than 10 years continously.

Pvc paver mould designs

The PVC paver moulds are vital the construction industry uses to aid in manufacturing premium paver blocks. We manufactures first quality PVC mould intented for long usage.

Advantages of JR Pvc paver moulds

- Easy demoulding, moulds are flexible yet, have high dimensional stability.

- High finished pavers

- First quality moulds with long lifespan.

- Fine and smooth finished pavers.

Plastic paver mould designs

Flexible plastic paver moulds are used in the construction industry for creating interlocking blocks, also referred to as pavers, to be used for various pavement designs. The molds are typically built from top-quality plastic, carefully designed to produce the best quality pavers. They guarantee quality during the production process. Through these, molds, concrete or other types of materials can be formed into specific shapes. This results in interlocking pavers that offer durability, and visual appeal.

Advantages of JR Plastic paver moulds

- We use only first quality virgin plastic raw material to make plastic paver moulds.

- Moulds designed for high dimension stability high finishing.

- Molds made of plastic are incredibly sturdy and durable, making them resistant to wear and wear and tear.

- Molds for pavers made of plastic are offered in an array of sizes that allow the construction of paver pavements in various sizes and forms.

- They’re also more financially viable because of their low costs and long-lasting durability.

Conclusion

Paver moulds play an essential function in construction because they offer the framework needed to construct attractive and long-lasting pavements. They are an essential tool that allows contractors and builders to get precise and predictable outcomes. JR rubber industries will examine all aspects related to paver molds. We will also discuss their advantages, the types of molds, and the things to bear at heart when choosing the right one.

FAQ

What's the function of paver moulds in construction?

Paver moulds play a crucial function in construction, allowing us to make solid and attractive concrete pavers. Using paver moulds, we can effortlessly create stunning paving tiles gorgeous in shape and pattern.

What are the benefits that come with JR Plastic paver moulds?

- We use only the best high-quality virgin plastic raw materials to produce plastic paver moulds.

- Moulds are specifically designed to provide high-dimensional durability and a high finish.

- Moulds made from plastic are solid and long-lasting, which makes them resistant to wear and tear.

- Paver moulds made from plastic are available in various dimensions that permit making paver roads in many sizes and shapes.

- They are also more economical due to their cost-effectiveness and long-lasting durability.

What are the benefits that come with JR PVC paver moulds?

- Simple demoulding and moulds are pliable, but they also feature high-dimensional stability.

- High-quality pavers

- High-quality moulds that have longevity for a long time.

- The pavers are smooth and beautiful.

What are the benefits that come with JR Rubber paver moulds?

- High dimension stability.

- Rubber has a long lifespan.

- Easy de-moulding due to the non-sticky Coating of the Moulds.

- Smooth and Shiny surface for the Tiles and Paver Blocks.

- Any intrinsic patterns are effectively transferred to Stones due to the unique property of Rubber moulds.

- The vibration of the vibrator machine is transferred efficiently to the concrete mix, which ensures optimum strength for the paver.

- When procuring moulds, our customers expect a lifespan of 4-5 years. But globally, our rubber moulds have been continuously used for over ten years.