Home > PVC Moulds

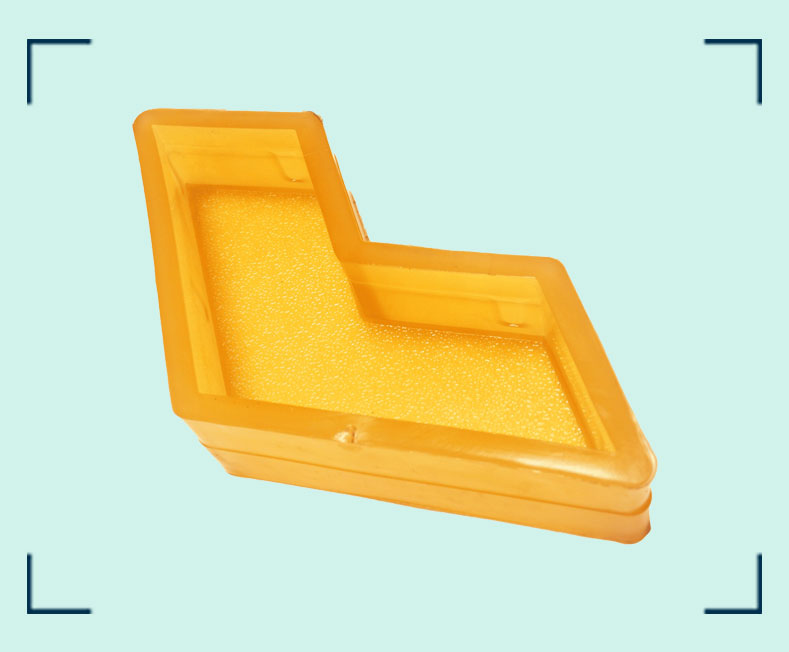

JR Rubber Industries is the pvc mould manufacturers of first quality pvc paver moulds. We provide the complete solutions for paver production with machinery, moulds, chemicals and technology and in-plant training. Our fine quality PVC moulds are made with virgin raw material. Our moulds have a long lifespan and high dimensional stability. The pvc moulds are designed with high engineering precision.There are numerous benefits of using pvc paver moulds.

PVC mould is highly flexible, that makes it easy to demold the tiles. Our products are designed to match all your demands and are premium quality paver block moulds. Over the past 29 years, we have never compromised the quality of our products and have always maintained consistency in the quality and designsOur perfect paver block mould design will match all the demands of the customers with premium quality at a reasonable price.

We are the leading mould manufacturers in India and producer of pvc paver moulds, rubber moulds, plastic moulds for pavers, kerb stone moulds, cover block moulds, zig zag paver moulds, wall tile moulds.We have never sacrificed the quality of our goods and have always used high-quality materials and designs over the past 29 years. We utilise our pvc paver moulds in several countries around the world, and they have a lifespan of more than 10 years.

Rubber Mould

PVC Mould

Plastic Mould

Compound Wall

Machinery

Chemical

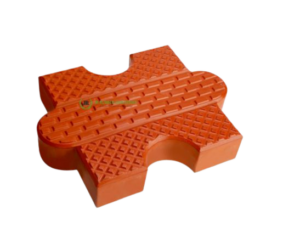

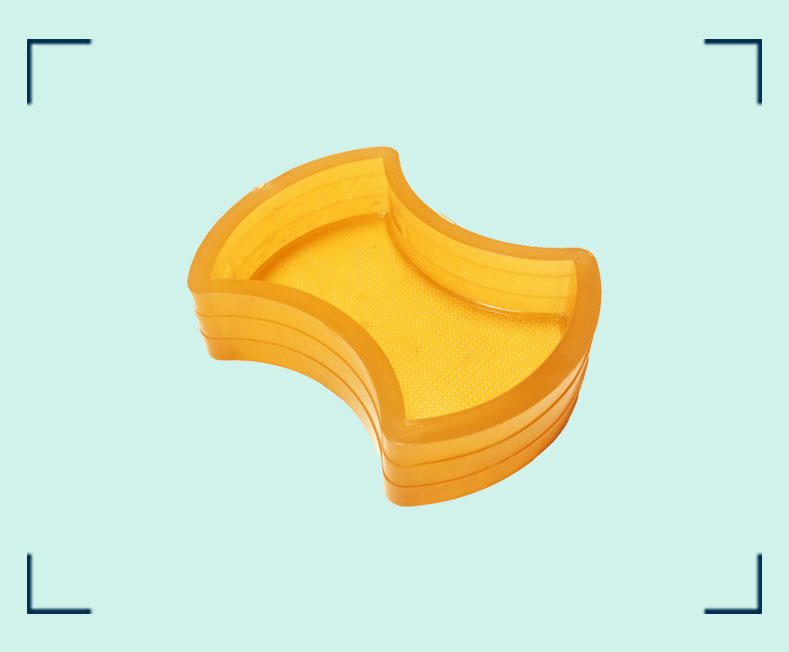

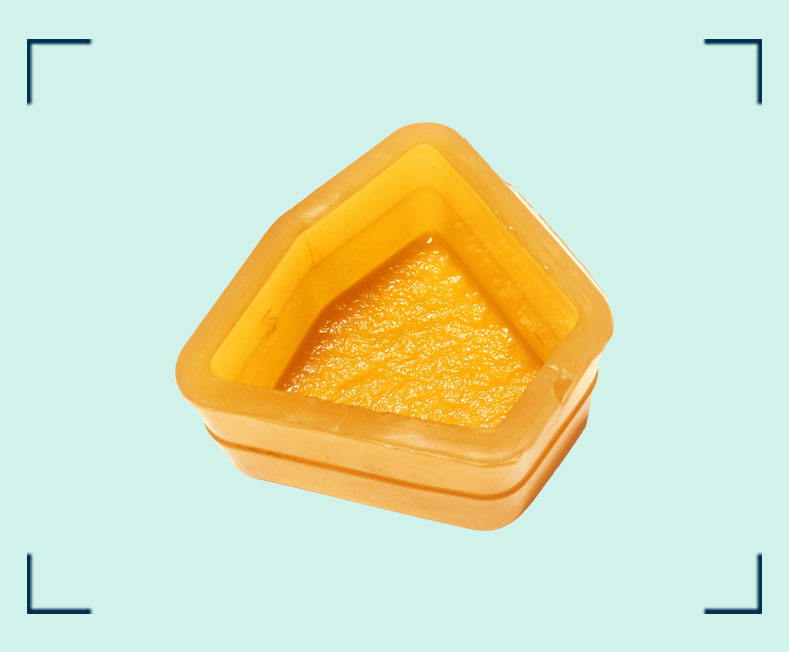

ZIG ZAG

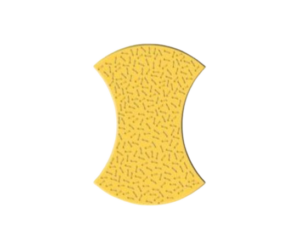

Elegance

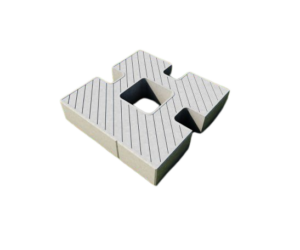

Dumbels

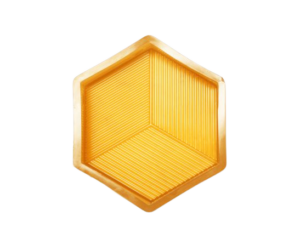

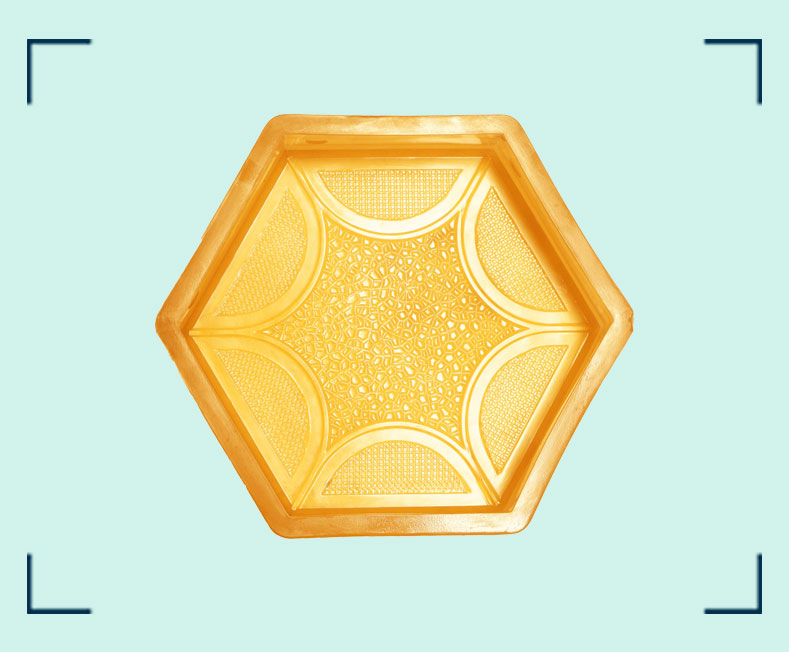

Hexagon

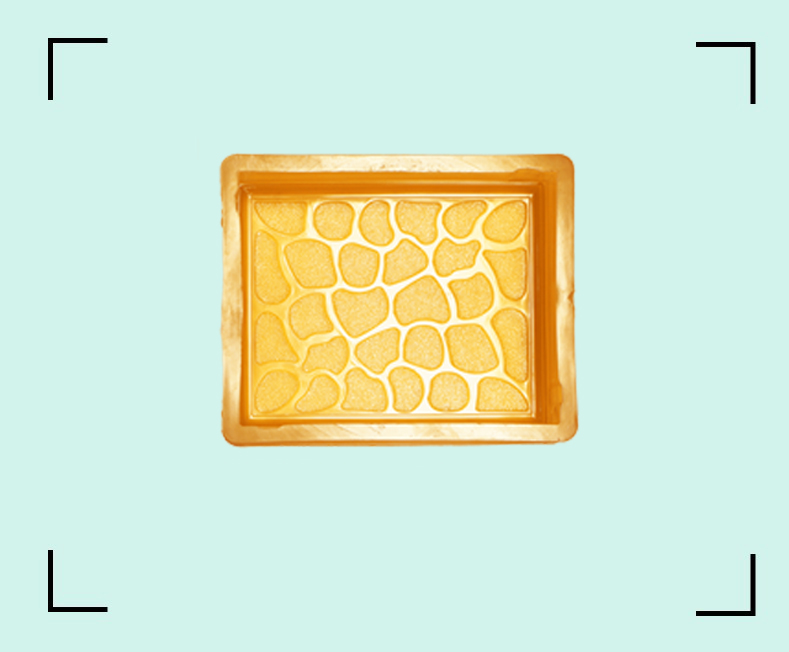

NATURAL STONE

Square and Rectangles

T Series

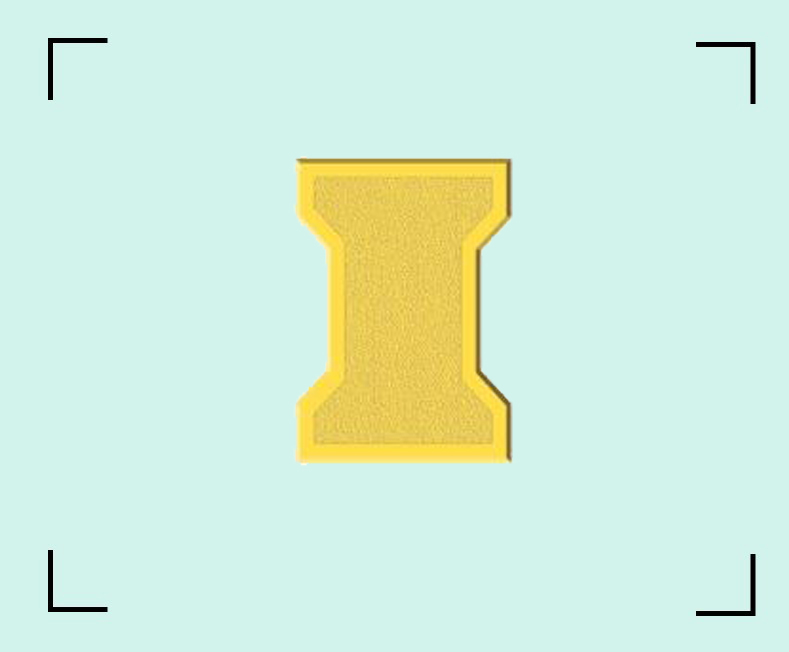

I Shape

3D Series

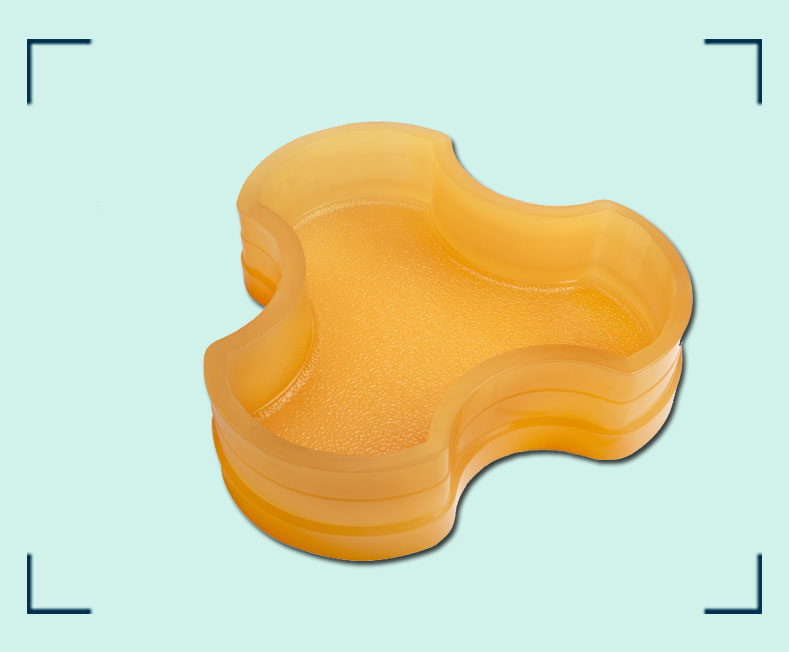

Combination Pavers

Floor Tile