PVC emerges as a standout choice in the quest for crafting and versatile material across various applications. In construction and landscaping, where the creation of robust and visually appealing pathways and pavement takes precedence PVC moulds have emerged as revolutionary tools.

These moulds often referred to as interlock mould, have redefined the very essence of how we conceive, and design, and these fundamental elements.

This blog post aims to delve deep into the realm of PVC moulds, shedding light on their extensive applications, myriad benefits, and the critical quest to locate dependable PVC moulds manufacturers.

In a world where durability, aesthetics and cost-effectiveness are paramount, PVC moulds stand as a beacon of innovation and excellence, providing a reliable foundation for the construction and landscaping industries to transform ideas into enduring realities.

The Versatility of PVC Moulds

PVC moulds are indispensable components across a spectrum of industries, most notably in the domains of construction and landscaping. These highly adaptable moulds hold a crucial position in the creation of an extensive array of products, with a primary emphasis on the production of paver blocks.

One of the standout qualities of PVC moulds is their exceptional durability. PVC, known for its resilience and resistance to wear and tear, ensure that these moulds withstand the rigorous manufacturing processes & the challenges of drivers’ environmental condition. This durability not only contributes to consistent product quality but also translates into long-term cost savings for manufacturers

The versatility of PVC Moulds is another significant asset. These moulds can be customized to create various shapes, sizes and designs, meeting the unique requirements of different projects. Whether intricate patterns of interlocking pavers or producing standardized tiles, PVC moulds offer limitless design possibilities.

Furthermore, PVC moulds are celebrated for their cost-effectiveness. Their initial affordability, long lifespan, and low maintenance requirements make them a preferred choice for businesses seeking to balance quality and budget constraints.

In the construction industry, PVC mould plays a pivotal role in shaping paver blocks, which are widely used for pathways, driveways, patios and outdoor applications. Their precise shaping ensures uniformity in size and design, resulting in aesthetically pleasing and structurally sound installations.

As the demand for innovative and durable construction and landscaping solutions continues to grow, PVC moulds remain at the forefront of these transformative industries, driving progress and pushing creative boundaries

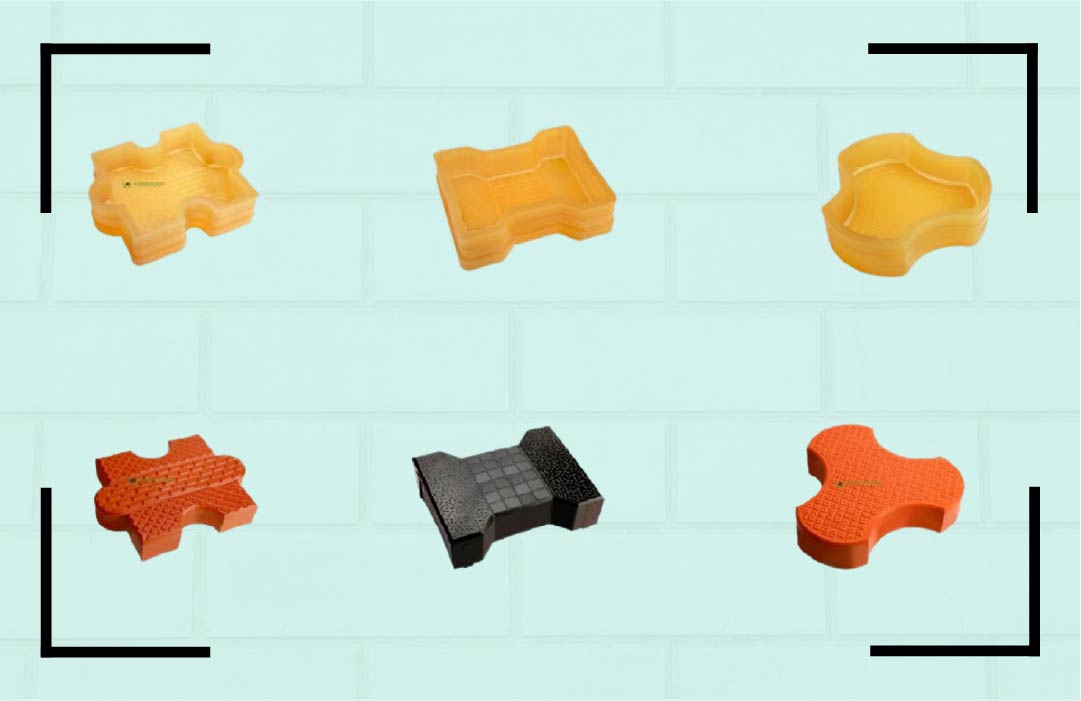

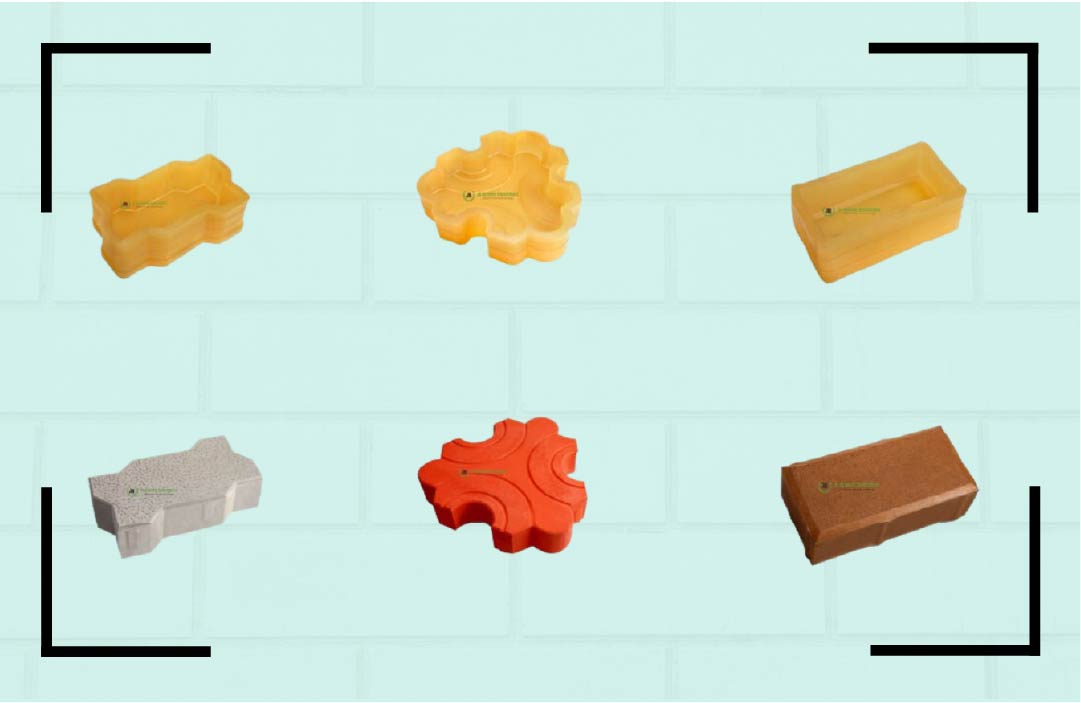

Different types of PVC Paver designs

- Zig-Zag Paver Mould: These moulds feature a zig-zag paver mould pattern that adds a dynamic and contemporary look to walkways, driveways and outdoor spaces

- Elegance Paver Mould: Elegance pvc paver moulds designs are known for their sleek and sophisticated appearance. They often come in smooth, solid colours and are favoured for creating modern, upscale designs

- Dumbbell Paver Mould: Dumbbell-shaped Pavers are typically used for creating borders or decorative edges. Their shapes resemble a dumbbell, and they add a charming detail to paved areas

- I-shaped Paver Mould: I-shaped moulds have a simple, linear design, making them suitable for creating clean and minimalist pathways or patios.

- Hexagonal Paver Mould: Hexagonal pavers create a unique honeycomb pattern when laid out. They are popular for their visually intriguing look and can be used to make intricate designs.

- Natural Stones Paver Mould: These paver are designed to mimic the appearance of natural stone, such as slate, cobblestone, or flagstone. They provide a rustic and timeless look to outdoor spaces.

There also exist many other designs, each PVC paver mould design offers a distinct visual appeal and can be combined or used individually to create diverse patterns and styles in landscaping and construction projects.

The choice of design often depends on the desired aesthetic, functional requirements and the overall theme of the project.

Exploring PVC Paver Moulds

PVC Paver moulds represent a pinnacle of PVC mould versatility, finding their place as one of the most sought-after applications. These moulds are expertly engineered to give rise to intricately detailed and visually captivating paver blocks. Their design precision and adaptability make them an ideal choice for elevating the aesthetic appeal of various outdoor spaces.

Whether it’s crafting a mesmerizing herringbone pattern for a driveway, creating a welcoming garden path, or transforming a plain patio into a work of art, PVC paver moulds shine.

Their ability to uniform and precisely shaped paver ensure not only a pleasing visual outcome but also a functional one. These moulds have effectively blurred the lines between durability and design, demonstrating that practicality need not compromise aesthetics.

In the world of construction and landscaping, PVC paver moulds continue to play a pivotal role in elevating outdoor spaces to new heights of beauty and functionality.

Key Advantages Of PVC Paver Moulds

- Durability: PVC paver moulds are known for their longevity, ensuring they can withstand the rigorous of heavy usage over time. Whether it’s extreme weather conditions or high foot traffic areas, PVC paver moulds stand the test of time.

- Cost-Effective: PVC paver moulds are not only durable but also affordable, making them an excellent choice for businesses looking to reduce production costs without compromising on quality.

- Smooth Production Process: PVC moulds are easy to clean and maintain, reducing downtime and ensuring a smooth production process.

Unveiling PVC Moulds Manufacturers

Choosing a dependable PVC mould manufacturer is paramount. At JR Rubber Industry, We proudly distinguish ourselves as industry leaders, renowned for our unwavering commitment to unmatched quality and expertise. With a proven track record of excellence, we stand as your trusted partner, ensuring that your PVC mould needs are met with precision, innovation, and a relentless pursuit of customer satisfaction. When it’s the quality and reliability you seek, JR Rubber Industry is a name you can trust.

Why Choose Us ?

- Experience: With years of experience, we have honed our craft and perfected the art of manufacturing PVC moulds. Our expertise ensures that you receive top-notch products that meet and exceed your expectations.

- Personalized Solutions to Clients: We understand that each project is unique which is why we provide personalized solutions to every client.

- Quality Assurance: At JR Rubber Industry, quality is our top Priority. We employ strict quality control measures to ensure that every PVC mould that leaves our facility is of the highest quality and free from defects.

- Long life span: We provide high-quality products with a long life span

Conclusion

PVC Moulds, including PVC paver moulds, are essential in various industries, offering durability, cost-effectiveness, and versatility. When searching for reliable PVC mould manufacturers, JR Rubber Industry stands out as the Preferred choice due to our experience, customization options, quality assurance, and commitment to sustainability.

For all your PVC mould needs, trust JR Rubber Industry to always deliver excellence. Explore our wide range of PVC moulds and experience the difference for yourself.